Photo etching is a process which uses chemicals and precise light exposure to create all kinds of metal parts. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

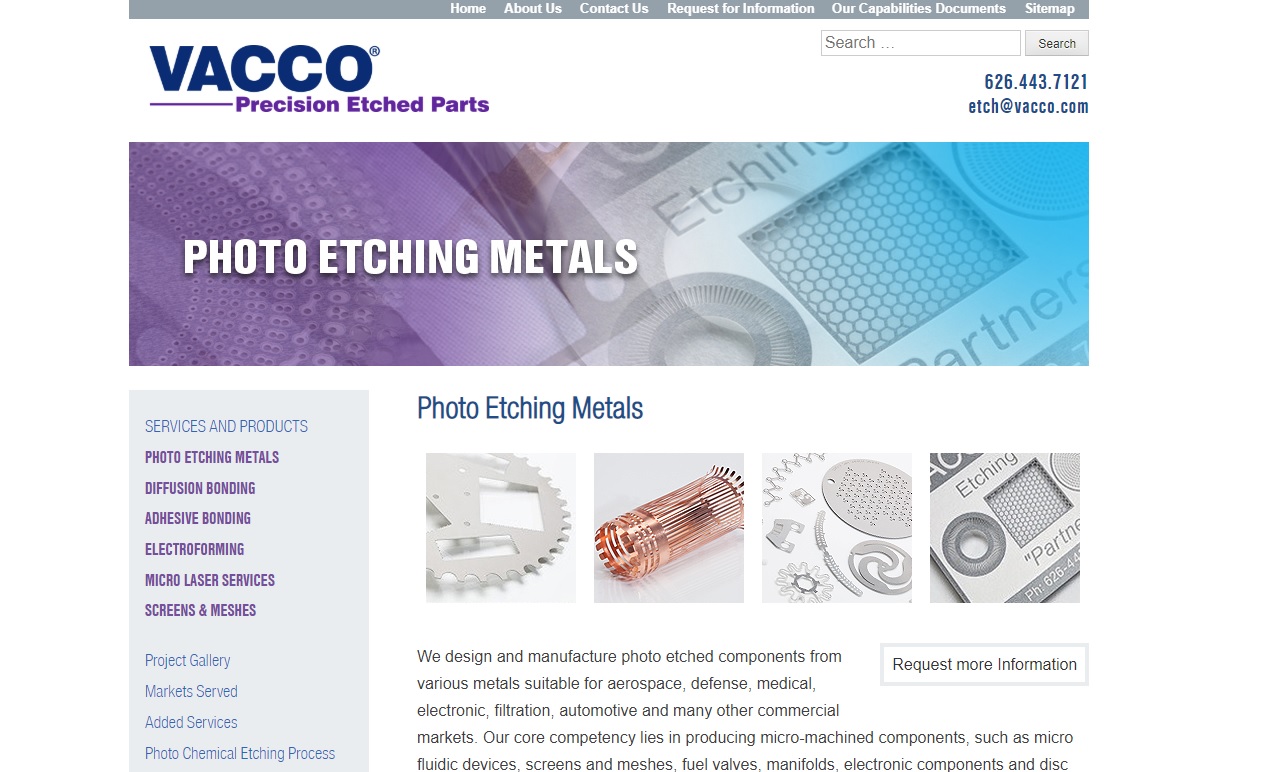

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

At Bazzill Engraving, we do personalized, industrial, custom, metal engraving and plastic engravings. Common materials that we use are hardened metals, stainless steel, aluminum, brass, copper, bronze and many others. For over 34 years we’ve been serving the southern Arizona valley, so contact us today for guaranteed success!

When it comes to engraving services, Engrave It Houston gets it done quickly and efficiently. As the premier source for custom engraving our dedicated staff will work with you every step of the way. We use state of the art equipment for a number of services including sand blasting, screen printing, rotary engraving and chemical etching. Visit our website for more information.

Metal Craft provides CNC machining services for medical, computer and aerospace industries. We strive to exceed customer expectations of quality, service and innovation. Whether you require CNC milling, grinding, turning or many other processes, skilled professionals guide you from start to finish. We also do laser etching and passivation.

More Photo Etched Part Companies

Photolithography is a process by which patterns are formed using photoresist covered substrates, or molecules acted upon by enzymes. The photoresist is then developed when it is exposed to ultraviolet light and viewed through a photo mask.

The substrate is then etched, and the photoresist then acts as a barrier that only allows the chosen part of the etched material to be etched. Photo etching produces detailed metal parts.

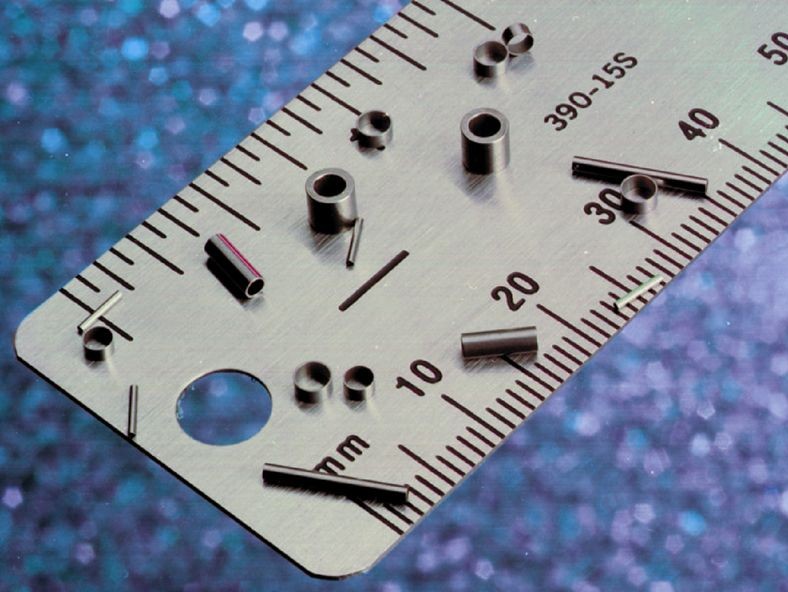

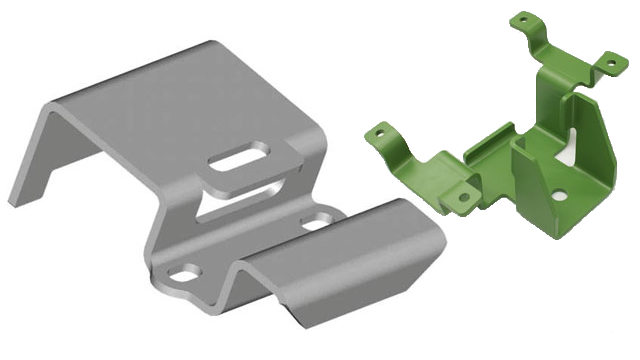

Photo etching's intricate method of cutting and engraving metal produces extremely thin metal, usually ranging from .002 to .2 inches in depth. A number of materials can be turned into photo etched parts, including aluminum, brass, bronze, silver, copper, nickel, steel and iron.

These parts are produced through either wet etching or dry etching. Wet etching works through the dissolving of a material in a chemical solution, while dry etching works by dissolving a material using ions or vapor.

Industries that use photo etched parts include the medical, aerospace, commercial, electronics, automotive, computer, dental and defense industries. Photo etched parts are very difficult to reproduce. This uniqueness may be advantageous or appealing in some industries, like aerospace, electronics or defense.

Another advantage of photo etched parts is their overall reduced costs. The flexibility photo etching allows in its design and products allows for more variety in material choice and eliminates stress on the product. Also, photo etched materials are produced at a much lower tooling cost and because photo etching is a burr-free process, no additional money need be spent on deburring.

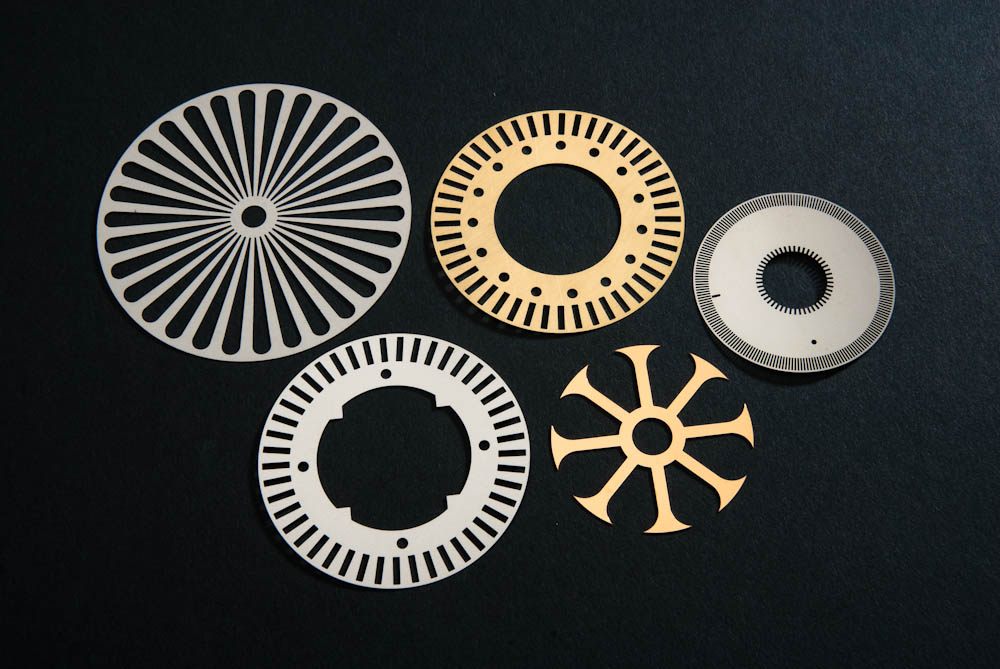

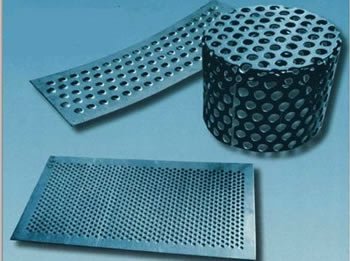

Photo etching, especially wet etching, offers higher imaging accuracy. Examples of etched parts include filters and sieves, needles and blades, surfaces and precision parts.

Photo etched filters and sieves can be important both in automobile and food industries. In the former, they can be used in fuel injection systems or as last chance filters in hydraulic systems.

In the latter, sieves are used in such applications as coffee machines or for sugar production. Needles and blades are primarily used in the medical industry, as complex lancets, scalpel blades, micro-saws, micro-combs and the like. Surfaces treated with or structured with photo etched parts can serve many interesting functions.

Surfaces can contribute to a more rapid growth of bone cells, better adhesion and reduced maintenance time in the mechanical engineering sector. Precision parts include grids, contacts, diffusers, coding disks and technical springs.

With all of their positive attributes and their flexibility, photo etched parts are the best choice for current technology.

Broaching

Broaching CNC Machining

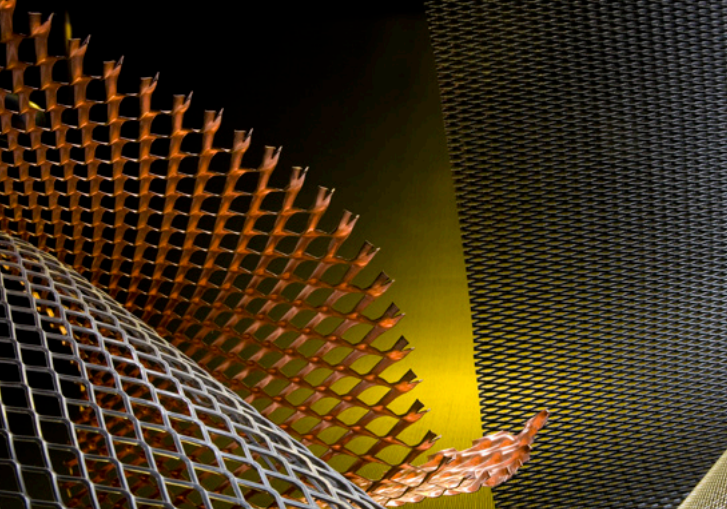

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

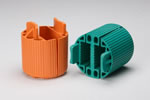

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services