The process of chemically altering a material to create certain desired shapes and dimensions is called chemical machining. Chemical machining is accomplished by removing specific material with a controlled chemical attack using acids or alkalis. A chemical process gradually transforms the metal into metallic salt, which is eliminated in the final state. In addition, an etching-resistant material called “maskant” or “resist” protects areas where the material cannot be removed. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Chemical Machining Companies

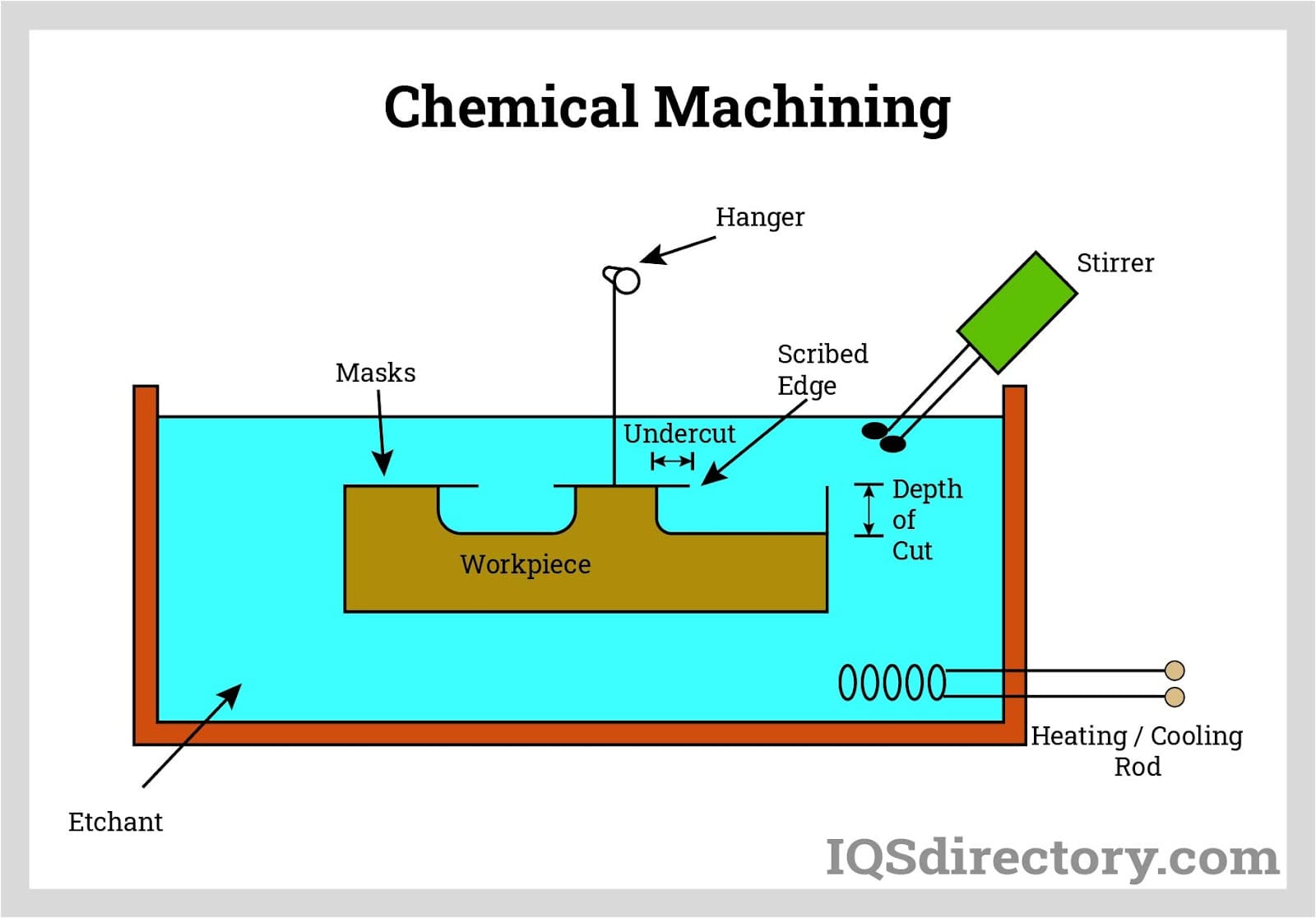

Almost any material, including metals and ceramics, can be machined chemically. Before being washed in clean water, the component to be machined is first cleaned in trichloroethylene vapor or a mild alkaline solution at 176 to 194 °F (80 to 90 °C). Coating the component using a spray or a dip removes grease and dust; thorough cleaning guarantees that the coating or masking chemical will adhere well. After being cleaned, the component is dried and the maskant material is applied. This material can then be sliced and peeled, used for photoresist, or screen-printed. Etching is used to finally remove the metal.

Chemical Machining Working Principle

Chemical etching is the basis for chemical machining. The workpiece's portion that needs its material removed is exposed to the etchant. The metal is protected from chemical attack by coating the metal with waxy ground. The etchant uses masking to make contact with the material.

Chemical Machining Process

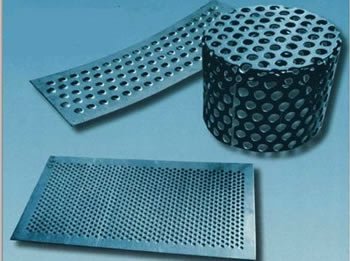

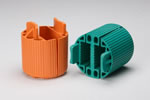

The procedure can be used for various tasks, including milling, blanking, and engraving. The many chemical machining techniques can be divided into the following categories:

- Chemical milling

- Chemical blanking

- Chemical engraving

A jet of a reactive gas, such as chlorine, can perform chemical machining for certain purposes. For example, metal parts can be deburred using this technique, sometimes referred to as hot chlorine machining or gaseous chemical machining.

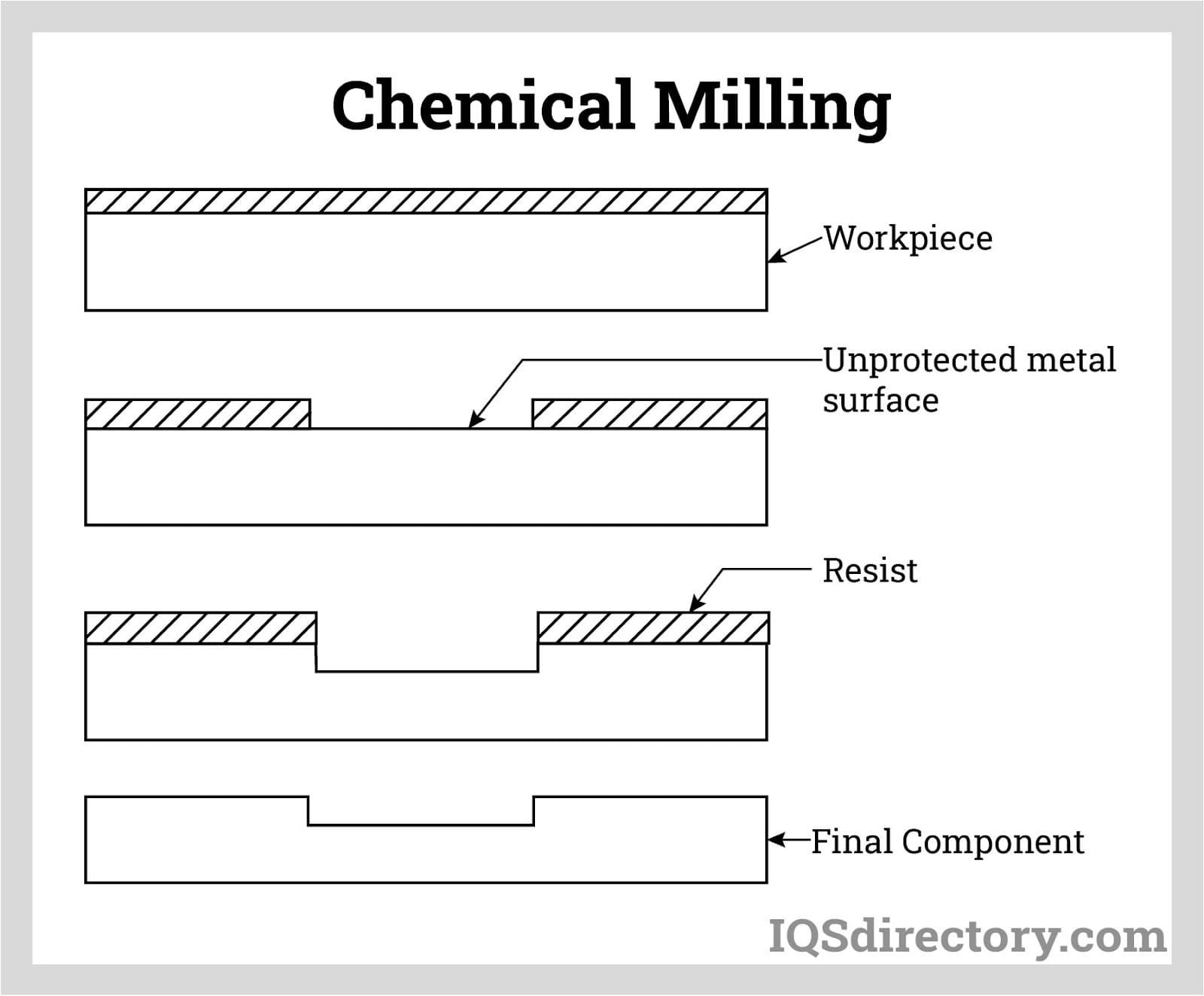

Chemical Milling

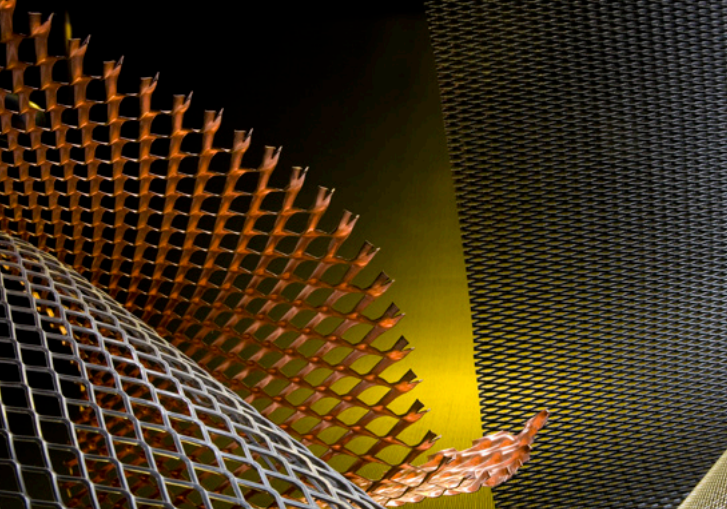

Chem milling, contour machining, and etching are other names for chemical milling. It creates forms by completely or partially removing metal from comparatively vast surface regions. The basic goal is to reduce weight in a shallow but complex profile by scraping away unneeded material from the surface, like an aircraft's skin.

The components are first immersed in trichloroethylene vapor to clean and degrease them and washed in clean water. The component is then painted, dipped, or sprayed with a cut-and-peel maskant (up to 0.2 mm). This fluid may be appropriate with a neoprene basis or another plastics solution that resists the etching agent's effects (permitting etching depths up to 10 mm). The desired shape to be processed on the work material is cut on the maskant using a scribing knife, and the unmachined portions of the maskant are peeled away once this has dried; if not naturally, through mild heating.

Typically, the portrayal is done using a template or a machining form that is within tolerance. The components are then fully submerged in a tank of chemicals, which dissolve (etch) away the metal exposed. Finally, the complete masking is removed from the component, and its surfaces are anodized or given temporary protective treatment after being etched to the requisite depth and washed to remove any traces of the etchant.

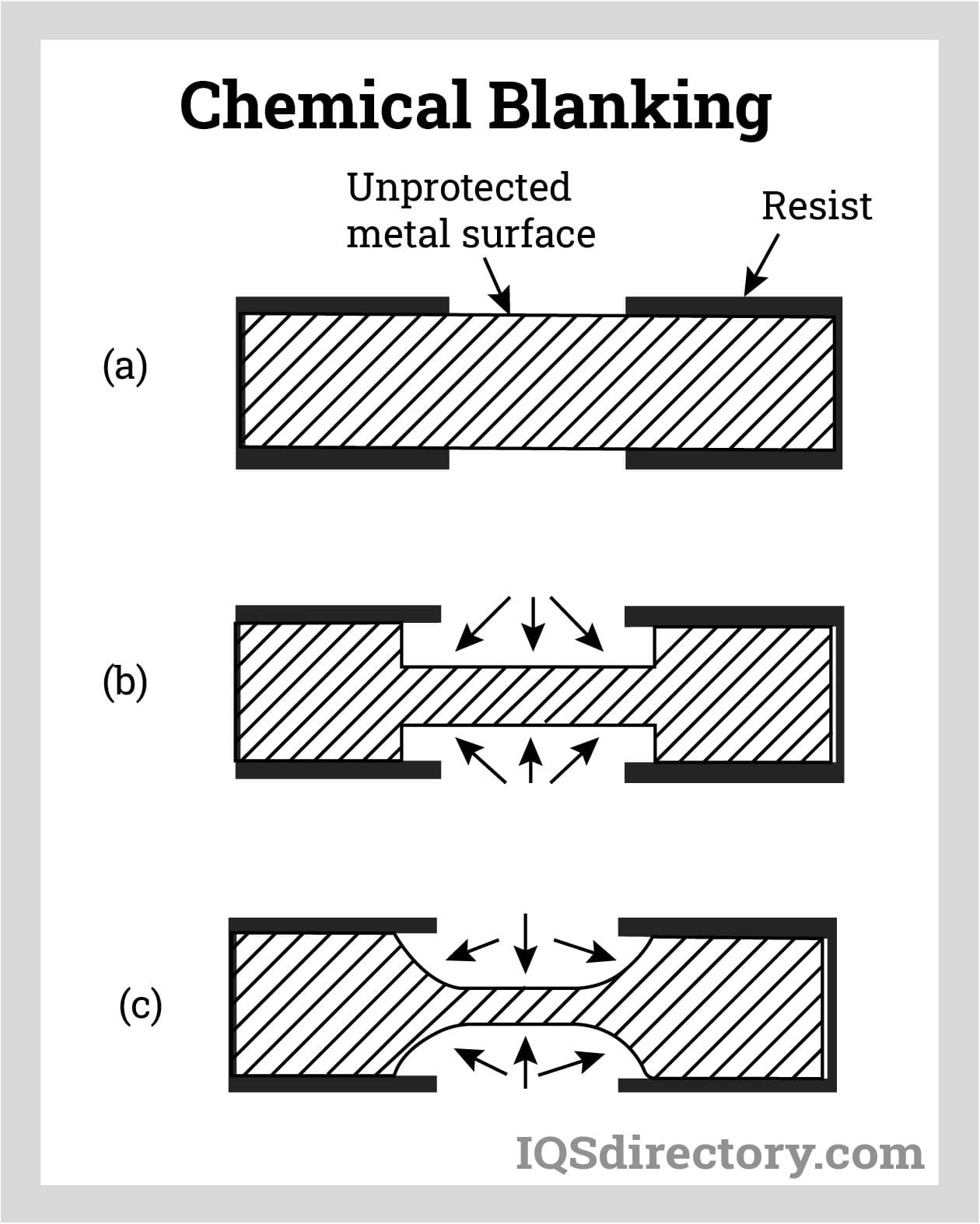

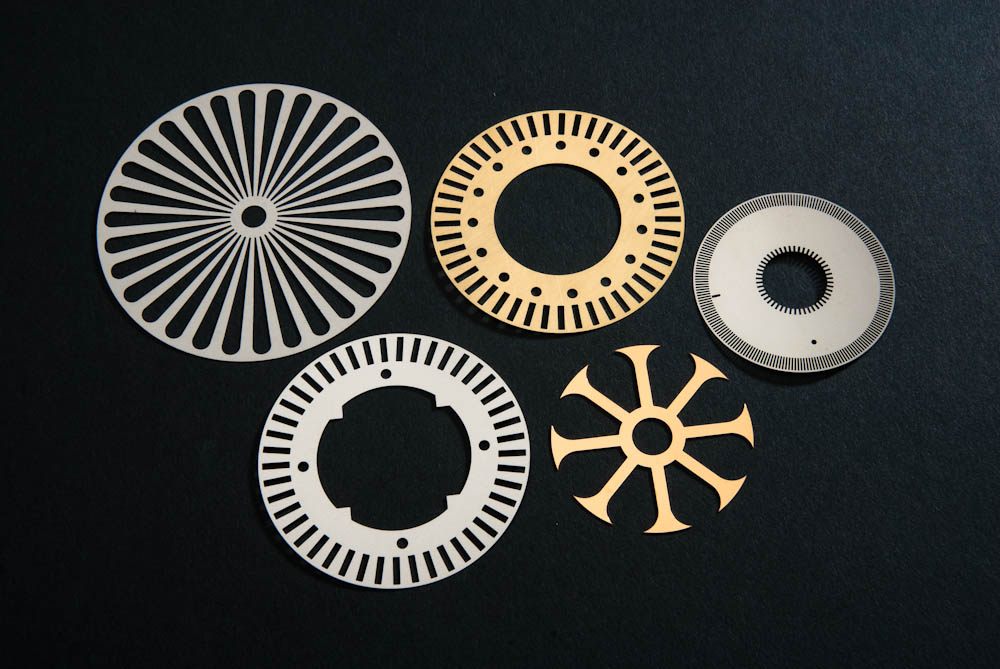

Chemical Blanking

Chemical milling consists of chemical blanking, chem-blanking, photo forming, photofabrication, or photo etching. In this procedure, chemical activity fully eliminates the substance from several locations. Their sheets and foils are mostly employed in the process. Almost any metal can be processed using this method, but it is not advised for materials thinner than 2 mm. The workpiece is cleaned, degreased, and pickled with acid or alkalis. After the cleaned metal has cured, the photoresist material is sprayed, dipped, or whirled onto the workpiece. Afterward, it is dried and cured.

It has proven possible to create images in photoresist materials resistant to etchants using the photographic technique. This maskant is not sensitive to ambient light but rather to a specific frequency of light, typically ultraviolet light. As with developing photographs, this surface is visible to the light through the negative or a photographic plate with the desired design. Following exposure, the picture is created. The unexposed areas are separated during the development process to reveal the bare metal.

The used metal is then put into a machine that draws it into the solution or sprays it with a chemical etchant. Hydrofluoric acid (for titanium) or another chemical can be used as the etching solution. The undesirable metal is removed after 1 to 15 minutes, and the completed item is now ready for a quick rinse to remove the etchant.

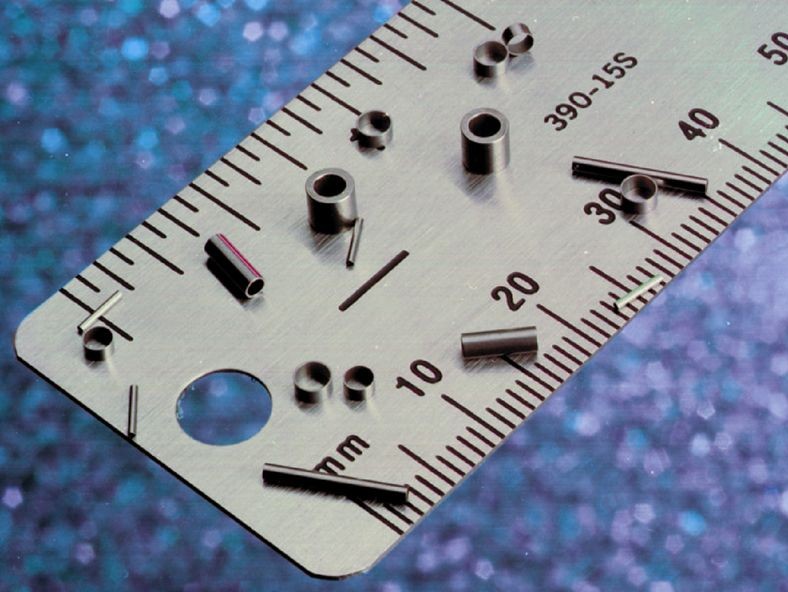

Chemical blanking can be used to make printed circuit cards, various engraving procedures, and the blanking of intricate drawings. Photoresist maskants are ideal for this; for example, 0.005 mm thick metal may be effectively etched. It is possible to maintain high accuracy to the order of +0.015 mm. An automatic photographic procedure can achieve a high production rate.

Application of Chemical Machining

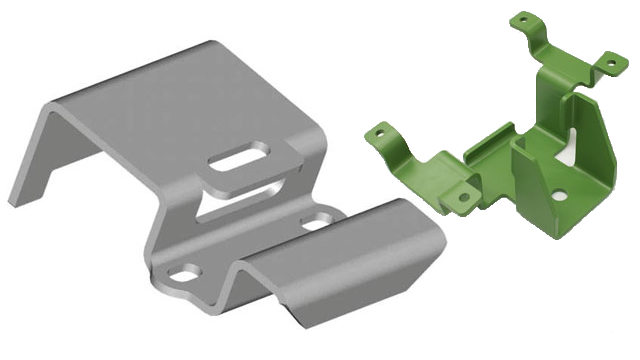

CHM has been used in several applications where tight tolerances and the depth of metal removal, which must be within a few microns, are requirements. The procedure results in a surface finish between 0.5 and 2 microns thick. A section of the entire surface of formed or irregularly shaped items, such as forgings, castings, extrusions, or formed wrought stock, is also partially removed from the metal. Creating detailed, burr-free stampings is one of the main uses of chemical machining.

Choosing the Correct Chemical Machining Company

To make sure you have the most constructive outcome when purchasing Chemical Machining from a Chemical Machining Manufacturer, it is important to compare at least 4 or 5 Manufacturers using our list of Chemical Machining suppliers. Each Chemical Machining Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Chemical Machining company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Chemical Machining businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services