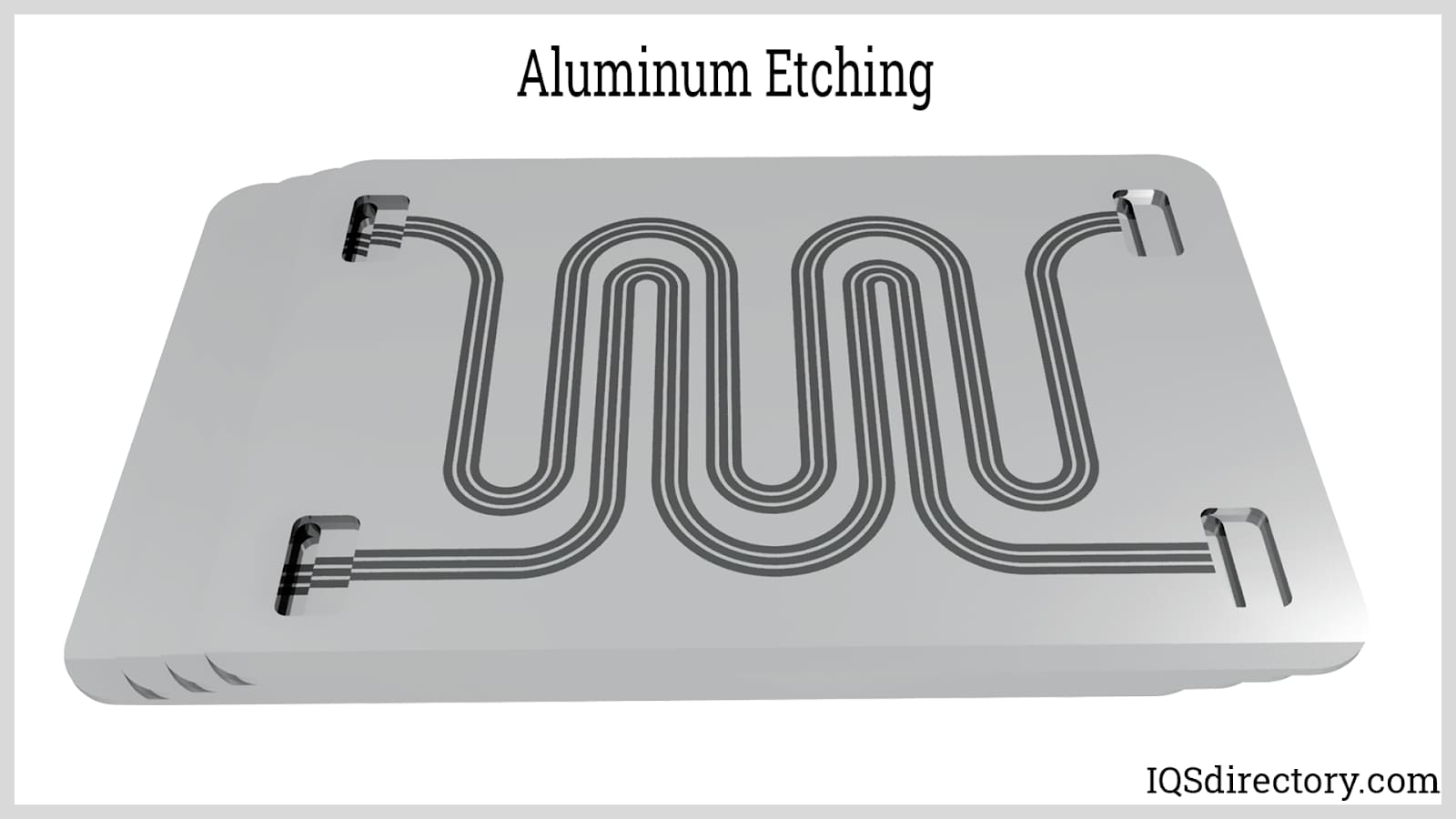

Aluminum etching companies use environmentally friendly and effective chemicals in manufacturing etchants. Aluminum etching is the process of using an acid etchant to selectively dissolve away the metal until a crisp, burr-free component is left. Aluminum etching is quicker, safer, and more controllable than traditional milling techniques, with components exhibiting higher-definition features that cannot be produced using other technologies. Chemical etching is defined by how it keeps the material’s properties, making parts with clean profiles, no heat-affected zones, and no stress or burrs. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Aluminum Etching Companies

In precision applications requiring strong but lightweight materials, aluminum and its alloys are often the metals of choice. Not only does aluminum exhibit excellent strength-to-weight ratios, but it is naturally corrosion-resistant, providing the perfect fit for extreme environments. Additional characteristics that make aluminum attractive include its high conductivity and is both ductile and malleable.

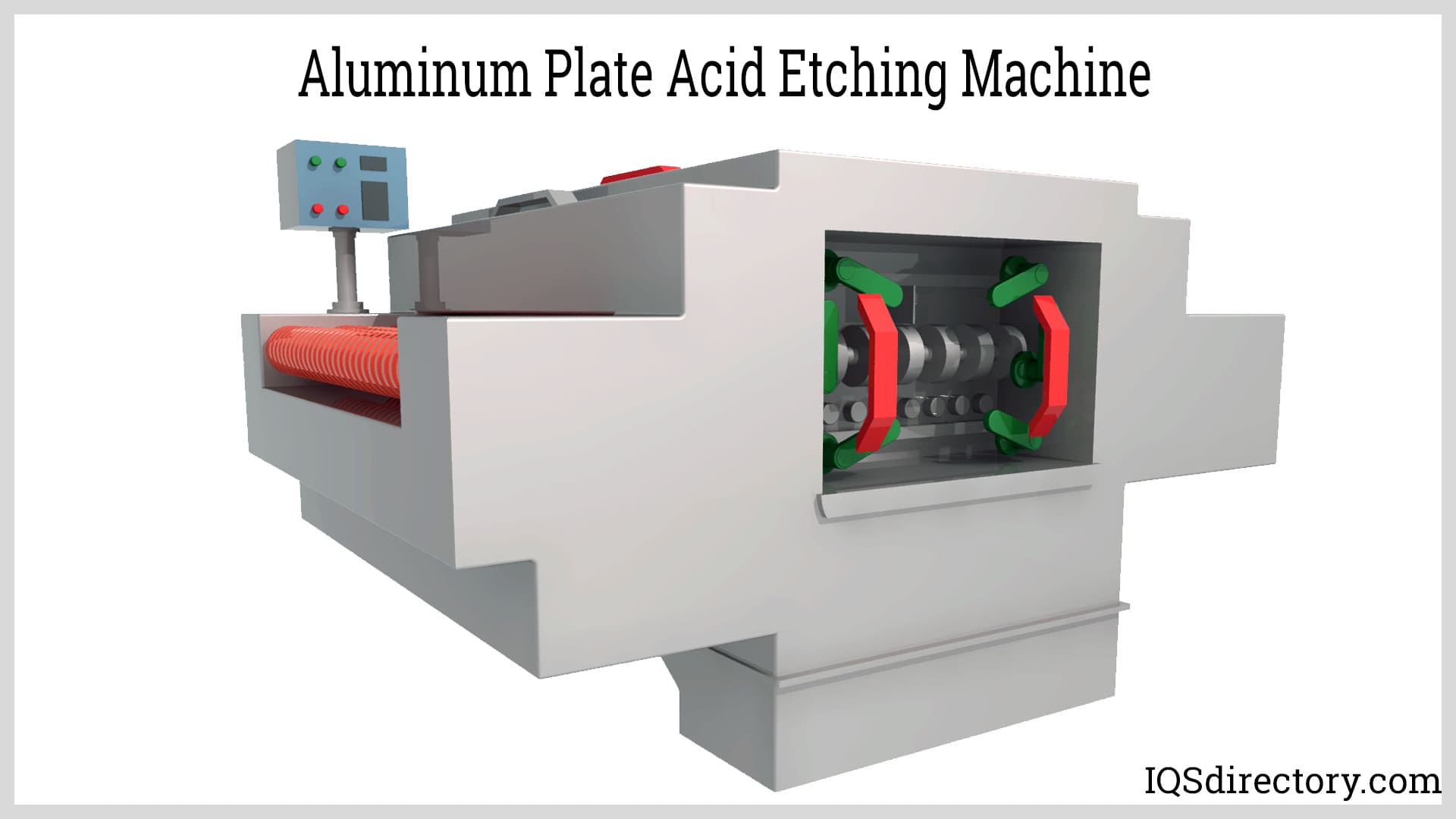

Aluminum Etching Mechanism

Nitric acid is commonly used in aluminum etchants to oxidize aluminum, phosphoric acid to dissolve aluminum oxide, methanolic acid to wet and buffer surfaces, and water dilution to determine the etch rate at a specific temperature. Because aluminum is an isotropic material, its etching is very exothermic. If no agitation is used, under-etching of the resist mask will result in local heating (increased etch rate) and super-proportional under-etching of the mask. Etch homogeneity is decreased by intense hydrogen gas bubbling. By stopping the etching every 30 seconds and briefly submerging the surface in DI water, which causes the hydrogen gas bubbles to disappear momentarily, it is possible to increase the uniformity of the etch rate. Etching often begins when the aluminum dioxide coating that covers every metal surface has been partially dissolved (by phosphoric acid). Because of this, the aluminum etching is impacted by the photoresist processing. Where the resist is mostly through-developed, the alkaline developers dissolve the aluminum dioxide more selectively (in regions with lower resist film thickness, near the edges of cleared structures, or below cleared structures with larger features). The process parameters may result in a spatially inhomogeneous start to the aluminum etching depending on the degree of intended or unwanted over-development and the interval between development and aluminum etching.

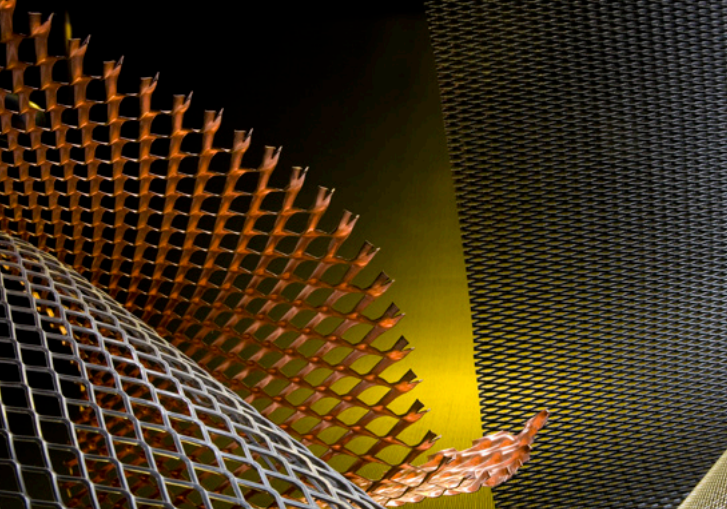

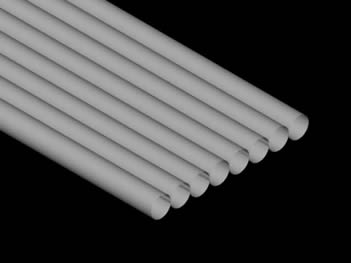

Chemically-Etched Aluminum Sheets

Traditional etching only partially removes the photoresist which, in turn, prevents some of the metal from being machined. This photoresist damages the etch and results in less-than-ideal products. Modern chemical etching processes for aluminum have now eliminated this potential problem.

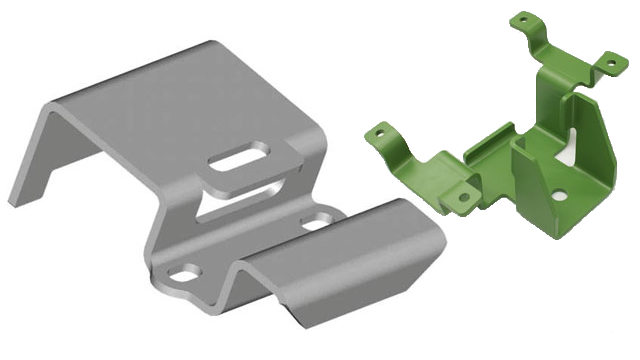

When aluminum interacts with chemical etchants, it produces heat energy (becomes exothermic).Strict process control is the secret to chemical etching success. Focusing on the chemistry of the etchant, temperature control, and metal cleaning and preparation are the keys to success in etching aluminum. Chemical etching offers a cost-effective, highly accurate, and quick manufacturing alternative to conventional sheet metalworking methods, such as stamping, lasering, and waterjet cutting. This cost-effectiveness is due to easily repeatable and inexpensive digital tooling. In addition, applications involving severe environments, such as those found in aircraft and using aluminum's material characteristics, are well suited for chemical etching.

Applications for Acid Etching of Aluminum

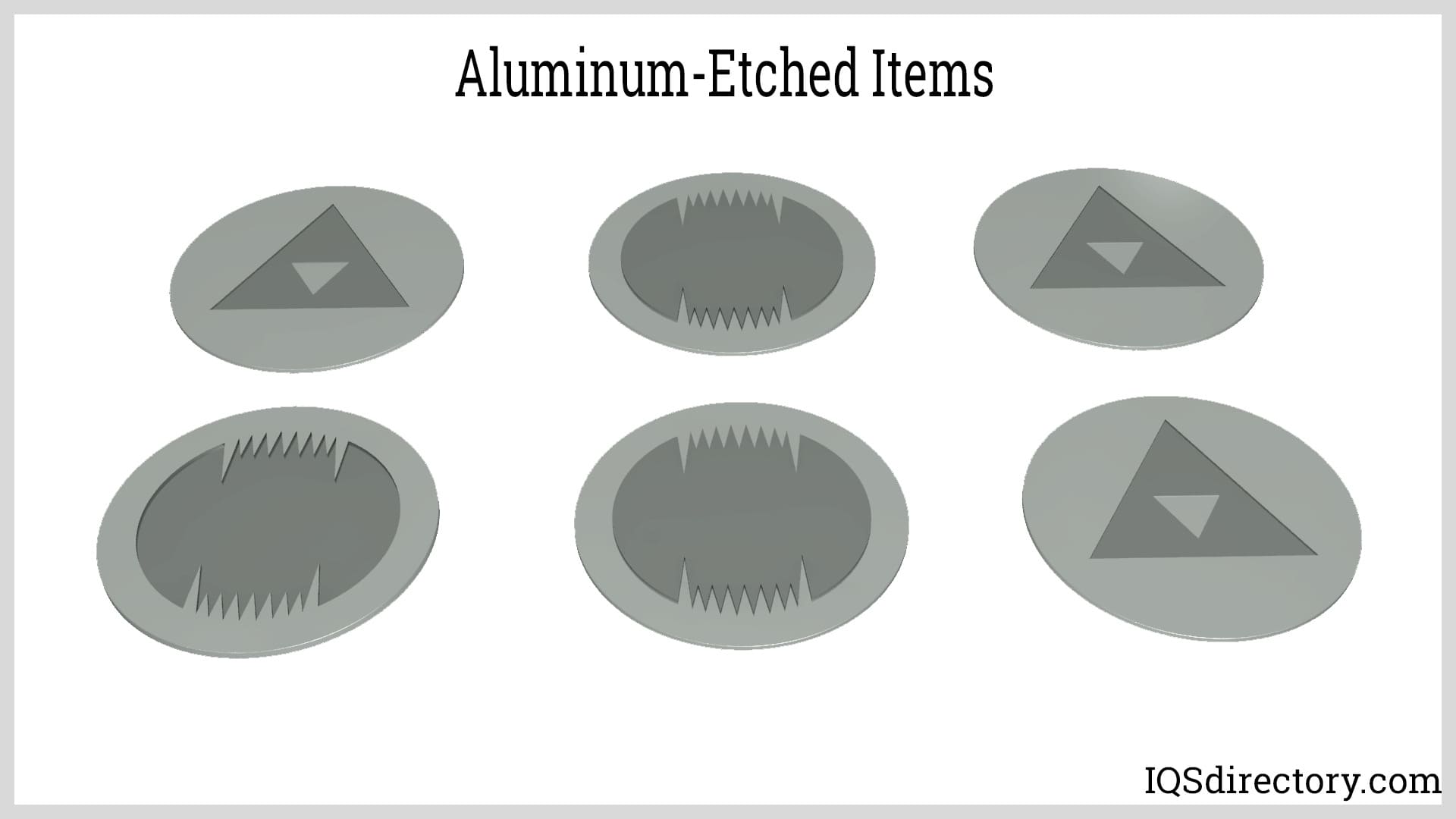

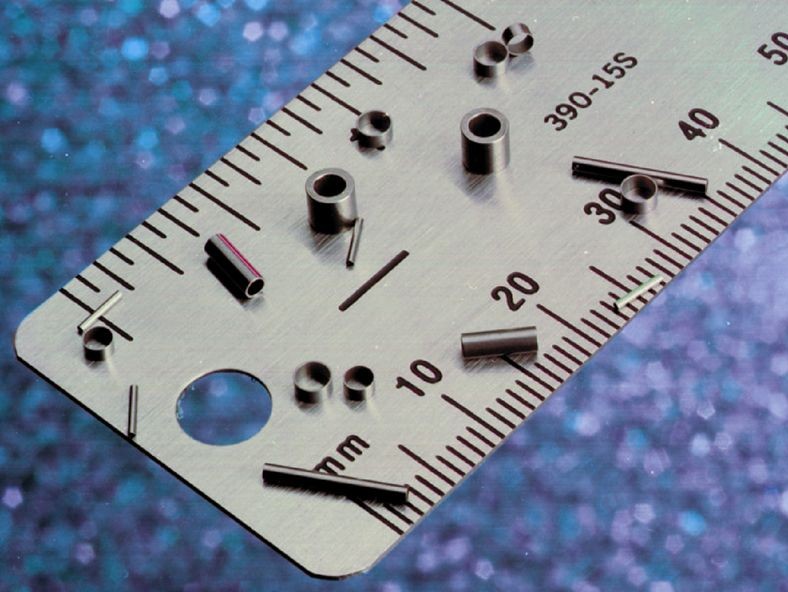

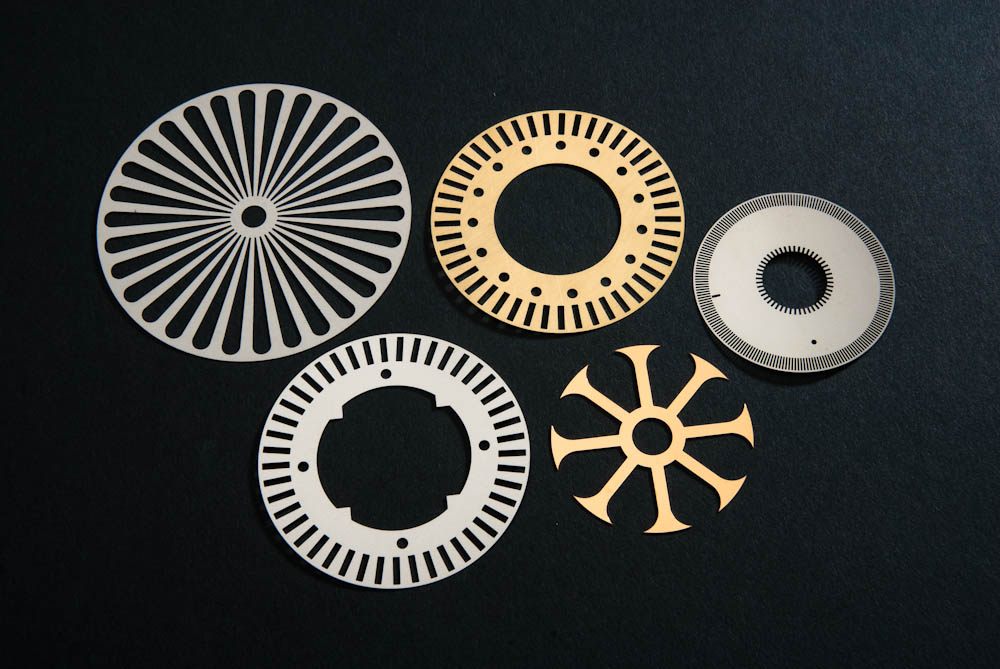

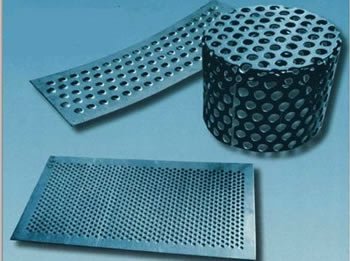

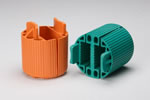

Etched aluminum is frequently used in the aerospace and automotive sectors. Aluminum plates are frequently etched. Electronic components like EMI/RFI shielding, shims, covers, lids, encoder disks, springs, and contacts are made using this method. Air intake grills and heater plates for aircraft can be made from metal. Aluminum dashboard surfaces, instrument dials, and coverings can be machined with various textures, profiles, and even logos for vehicle applications.

Small, printed circuit board components can also be made from etched aluminum parts since a quick, accurate, and reasonably priced technique allows for producing a large number of them at once.

Benefits of Aluminum Etching

Many businesses prefer aluminum over other materials because of the appealing qualities mentioned above. The aircraft sector, in particular, needs strong, lightweight components that can withstand high temperatures or stresses. Compared to other metals, aluminum has a higher fatigue limit. Heat transfer plates are one example of an aviation component with several lines simultaneously etched during the etching process. As a result, this component can be produced more affordably in large quantities than other processes.

Likewise the automobile sector benefits from aluminum etching with aluminum components like bipolar fuel cell plates that can be produced using a low-cost process. Similar to heat transfer plates, these pieces feature a lot of channels, so the metal etching procedure is more economical. In addition, due to the simultaneous etching of the metal's two surfaces, the procedure also saves time.

Photochemical etching can protect EMI/RFI shielding parts made of aluminum from the magnetic properties of nearby components in any industry that uses electronic systems.

Advantages of Aluminum Etching

- inventory and brand management

- rapid prototyping

- inherently burr-free parts, which are stress-free and have their physical properties unaltered

- cost-effective production

- high-precision machining

Choosing the Correct Aluminum Etching Manufacturer

To make sure you have the most productive outcome when purchasing Aluminum Etching from an Aluminum Etching Supplier, it is important to compare at least 6 Manufacturers using our list of Aluminum Etching companies. Each Aluminum Etching Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminum Etching business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Aluminum Etching businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services