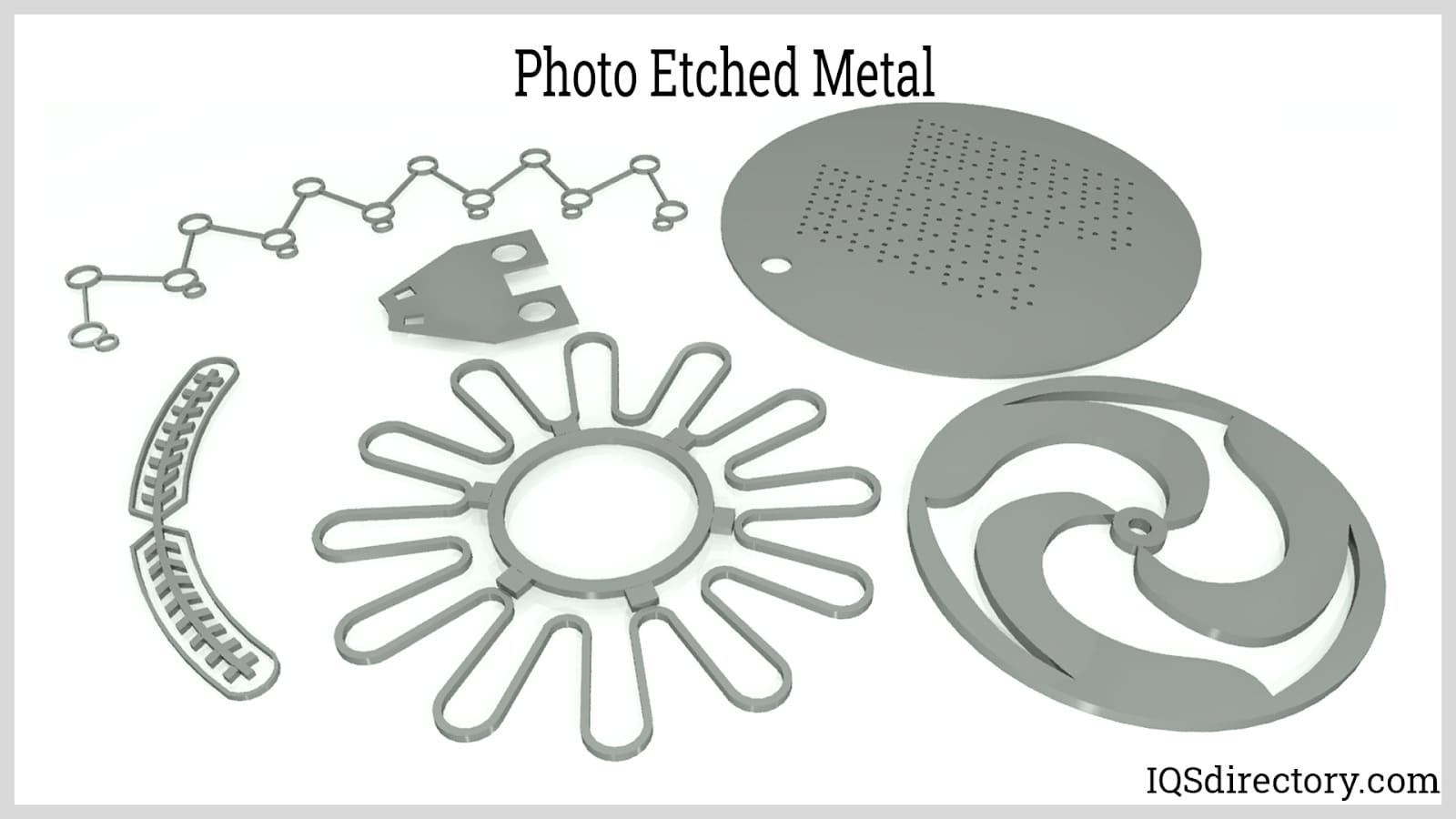

Photochemical etching is a subtractive, non-traditional machining process that uses chemical and photographic techniques to design and shape metal workpieces. After developing the design of the image on the workpiece, a strong chemical solution is poured over the workpiece. As a result, the workpiece corrodes selectively and removes all unnecessary material from areas that are not protected, leaving a sharp image or flawless part. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Photo Etching Companies

What is Photochemical Etching?

The areas that need to be removed or saved are picked up using photographic methods and procedures like photoresist imaging.

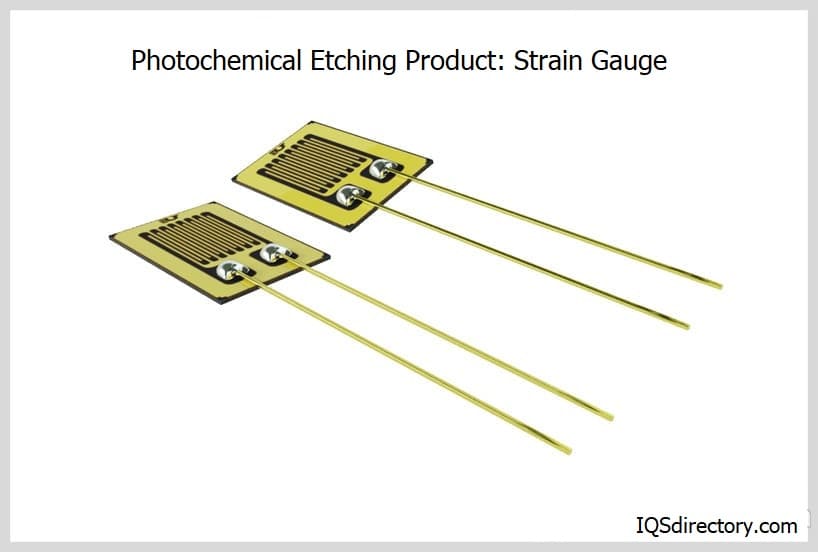

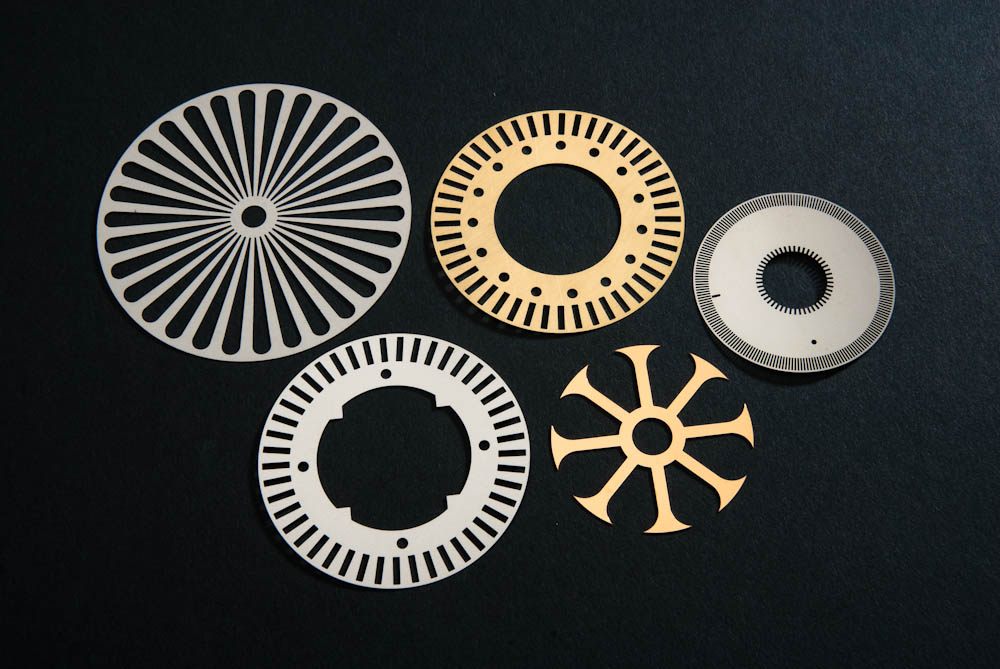

The main advantage of this machining process is that it manufactures and produces precision parts that are impossible to produce by traditional machining methods.

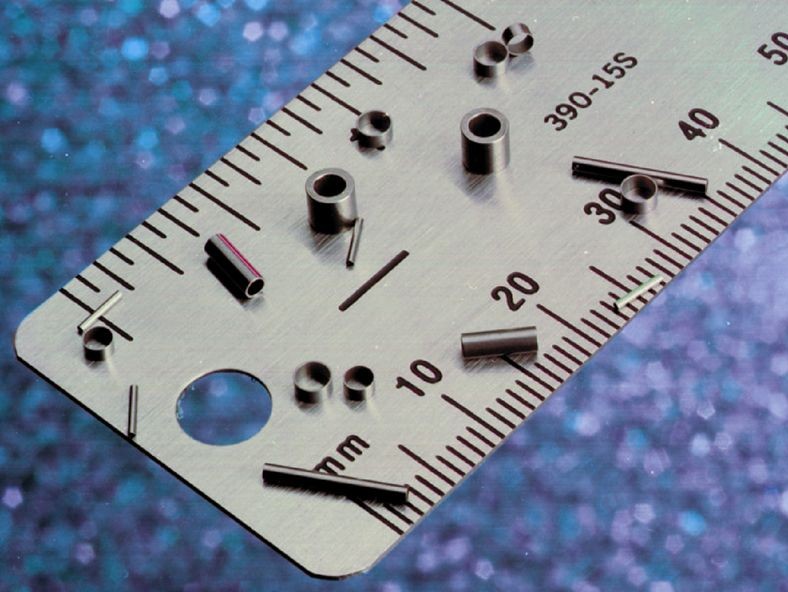

The photo etching process produces thin and flat parts, with the smallest of them about ten microns.

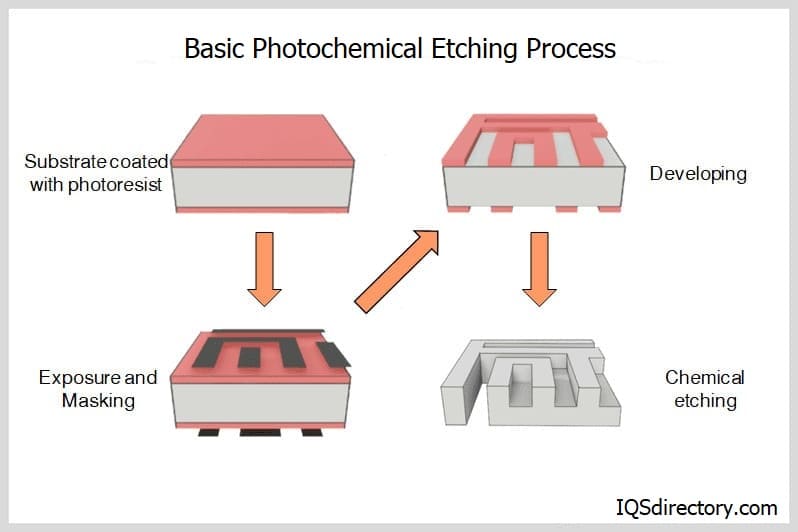

The Photochemical Etching Process

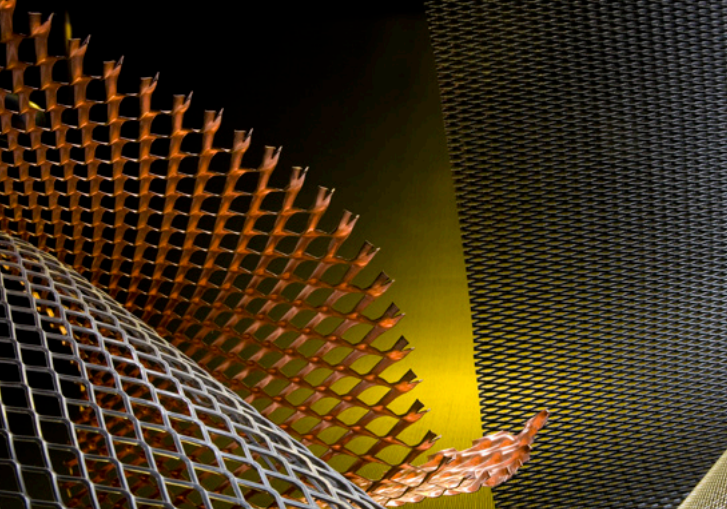

The photochemical etching process makes it possible to etch intricate and highly complex features into a range of different metals.

Photo Tool Plotting

The photographic negative of the artwork or profile desired is the photo tool. Engineering design software is normally used to come up with patterns. Then, the design and its parameters are converted into a photo tool before they are printed onto a photographic film. Photo tool dimensions are affected by the following:

Temperature and Humidity Variations

Dimensional variations are possible because of continuous changes in humidity and temperature. Measures taken to control these variations include using thicker polyester films or plotting in a controlled environment. If variations in humidity and temperature cannot be controlled, it is wise to use techniques such as laser direct writing.

Etch Factor

Most of the etchants act isotropically, producing undercuts. An isotropic reaction is considered more prevalent in long etching processes. Longer periods of etchant exposure are needed for deep etches, resulting in more significant undercuts.

Material Preparation

The workpiece undergoes cutting and cleaning prior to the application of photoresist coating. This is done to ensure that any dirt, grease, oil, or rust accumulated on the surface of the metal from its handling and primary processing will not stop the photoresist from adhering. There are two main procedures for cleaning: mechanical and chemical.

The latter method involves a mild pickling process in which the material is suspended in a solution containing degreasing agents and mild acids. The former method subjects the material to scrubbing and mild degreasing agents. However, chemical cleaning processes are much preferred over mechanical ones because there is less damage caused to the material.

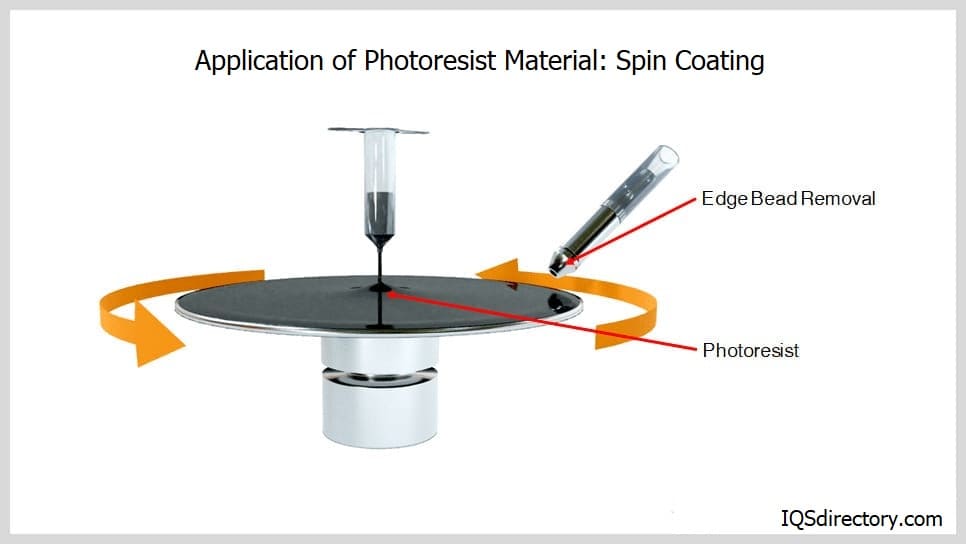

Photoresist Coating

Photoresists are very light organic materials that are deposited on the workpiece surface. They can cope with etching solutions and leave a well-defined image. When the coating is exposed to ultraviolet radiation, it becomes soluble or insoluble to the solvent, depending on the type. Photoresists are classified as positive or negative. Positive photoresists have areas that become soluble to the developer solvent when exposed. On the other hand, negative photoresists, when exposed to ultraviolet light, become chemically resistant to the developer solvent.

Soft Bake

In soft baking, the photoresist is heated or baked to release or vaporize the residual solvents. The process has to be under control since it is associated with a high evaporation rate that causes bubbles to form, creating voids inside the photoresist.

Alignment and Exposure

For multi-layered patterns, it is crucial to ensure the correct alignment of the photo tools. Exposure is a process where the image on the photo tool is brought to the workpiece with a photoresist.

The development of the photoresist follows the above. Then, hard baking is done using nitrogen blow drying and distilled water. The etching process then removes all the unprotected regions of the substrate or wafer by using chemical agents.

Photoresist Removal and Stripping

When the substrate structure required is made, the photoresist is removed. It has to be done very quickly without causing any damage. Various methods can be used to remove the photoresist material, such as solvents or oxygen combustion.

Photochemical Etching Applications and Advantages

The applications and advantages of photochemical etching include:

Applications of Photochemical Etching

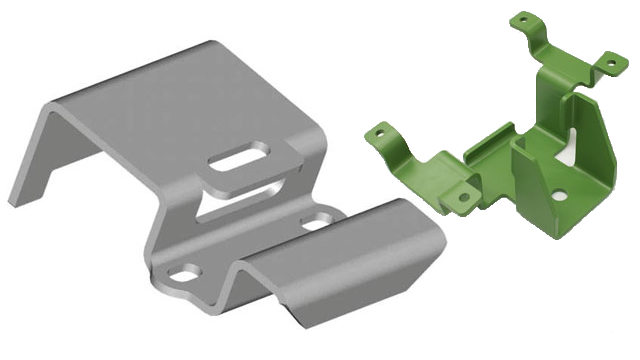

- Aerospace components

- Gaskets and seals

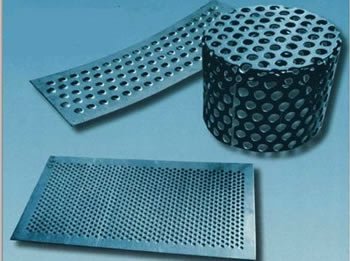

- Fine filters and screens

- Decoration

- Printed circuit boards

- Electronics

- Medical grade materials

- Automotive industry

Advantages of Photochemical Etching

- Reduced production time

- Less costly

- High precision

- Ability to produce small-scale products

Choosing the Right Photochemical Etching Company

To make sure you have the most productive outcome when purchasing Photochemical Etching from a Photochemical Etching Supplier, it is important to compare at least 4 Companies using our Photochemical Etching directory. Each Photochemical Etching Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Photochemical Etching company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Photochemical Etching companies with the same quote.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

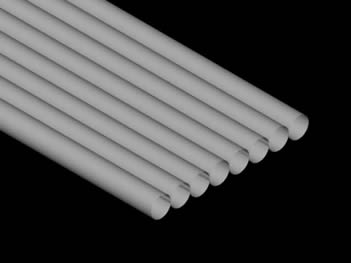

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services