Titanium is a highly durable material that is made from rock, clay, sand, or soil that contain ilmenite and rutile. These two minerals, when processed, produce titanium tetrachloride from which titanium is produced. Initially, titanium was an interesting laboratory experiment that has developed into a viable and practical manufacturing metal. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Titanium Etching Companies

The methods of getting titanium are complicated and difficult, which has given it the label of being rare. Parts that have been processed from titanium etching are used in several industries due to titanium’s luster, light weight, strength, and corrosion resistance. Titanium etching is used to create decorative items for apartment buildings, supermarkets, and high-tech industries as well as medical implants and aeronautical components.

What is Titanium Etching?

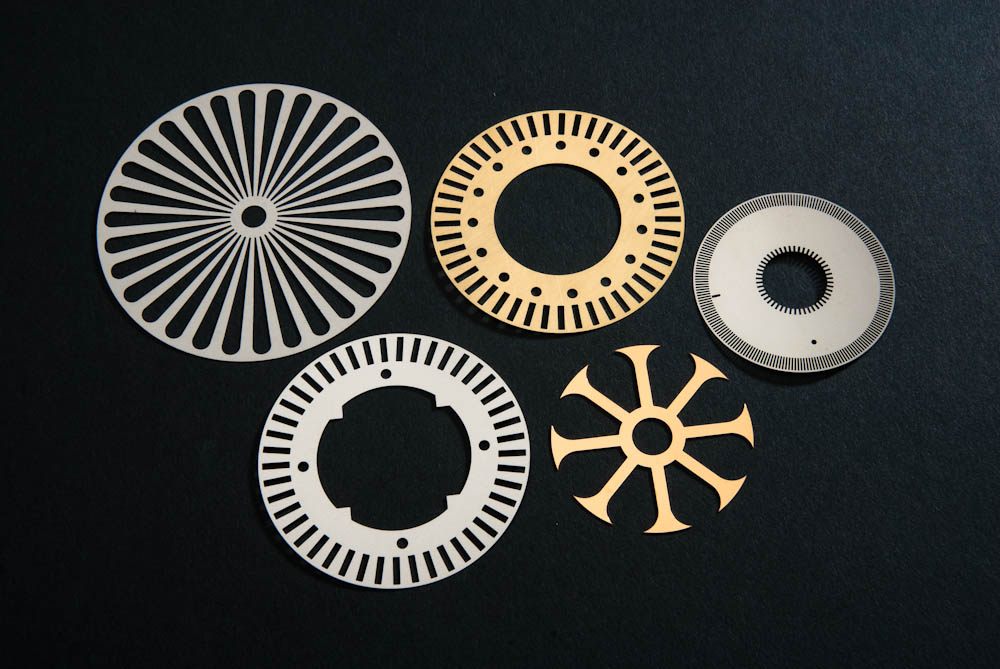

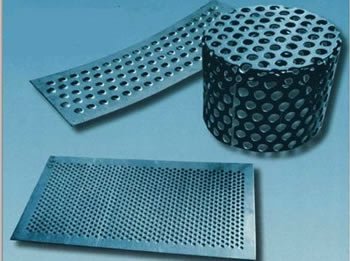

The etching process is a subtractive method of removing portions of metal from a flat metal surface. The process can leave a design, cut holes in the surface, or shape metal sheets for further production. Titanium etching follows the same processes of other etching methods.

Titanium etching is a machining process that is designed to dissolve away parts of a metal surface using some form of a reagent chemical. The nature of titanium etching creates the design or configuration in the metal without damaging its mechanical properties.

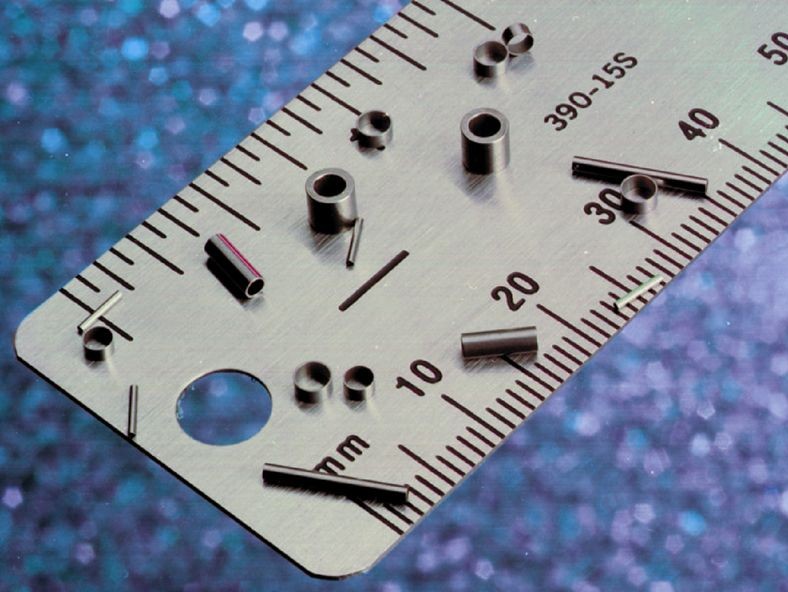

The weight, size, thickness, or type of titanium does not affect the titanium etching process. The material can be chemically etched if it is 0.01 mm or 1.0 mm thick. Sheets to be etched are from one to two feet.

The process of titanium etching involves placing a design, shape, configuration, or picture on a piece of laminated titanium using the photoresist method, a light sensitive material that forms a pattern or design on the surface of a metal. The areas where the photoresist material is not present on the metal will be etched away.

Titanium etching occurs using hydrofluoric acid (HF), which is combined with other chemicals to complete the etching process. The HF acid is able to produce high quality components and can be used on any of the various sizes of titanium sheets. Using HF produces etched products that are high quality, very stable, and rapidly repeatable.

Titanium Etching Products

Any operation or process that requires highly stable and durable components and parts relies on titanium etching to produce them. The various industries that use titanium etched materials include medicine, aerospace, defense, and vehicles for space travel. The fact that titanium is lightweight, strong, and corrosion resistant is what makes it so widely used.

For the medical industry, titanium is used for implants such as craniomaxillofacial implants and dentistry. The biocompatibility of titanium makes it an ideal material. To produce implants using titanium, the titanium etching process shapes components in such a way that they are malleable enough to contour to where they will be placed.

The rugged durability of titanium has made an essential part in the production of structural airframes. Its light weight, adaptability, and strength are the key reasons that titanium etched parts are a critical part of airframe design and construction. Titanium parts are used in highly stressed areas of an aircraft including wing structure and landing gear.

The medical use and aeronautical uses for components etched from titanium are just a few of its uses. The number possibilities are constantly growing as designers and engineers discover more and unique ways to use this strong and durable material.

Benefits of Using Titanium Etching

Titanium etching does not produce the typical kinds of stress that are found in traditional machining methods. The physical and mechanical properties of the metal remain unaltered after enduring manufacturing processes. This guarantees the strength and endurance of the final product to have the initial qualities of the metal.

The etching of titanium allows for complex, intricate, and complicated designs to be produced with the highest possible quality. Whether it is cutting holes in the metal or creating a wide variety of shapes, the designs, logos, patterns, and configurations are a precise replication of the initial design.

Though the production of the raw titanium is complex, in the production process, the etching of titanium is cost effective, limitless, and timely. Machines and equipment can easily be shifted and adjusted to meet any type of time constraints or deadlines.

Broaching

Broaching CNC Machining

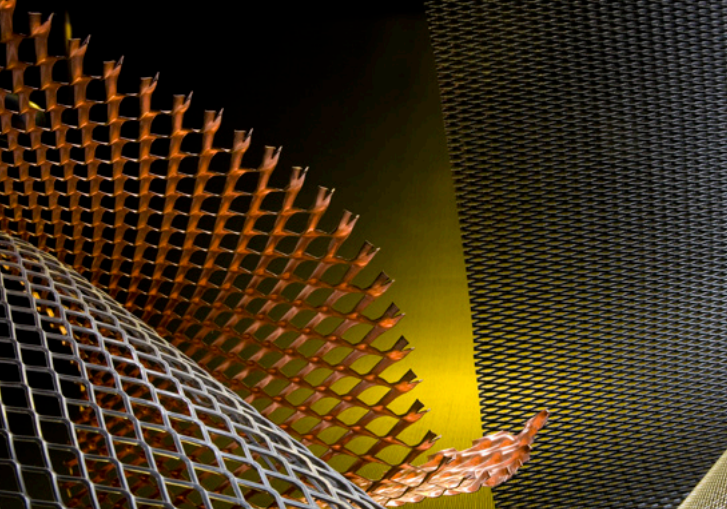

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

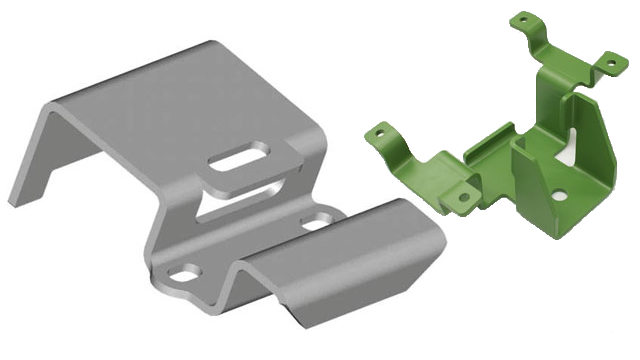

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

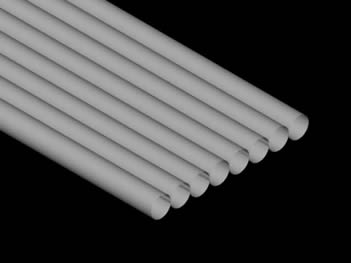

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services