It is still a chemical process and utilizes the same masking and etching technique, with one significant difference: instead of using masking material and cutting out the area to be etched, a photoresist is applied and developed through a patterned exposure to light. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

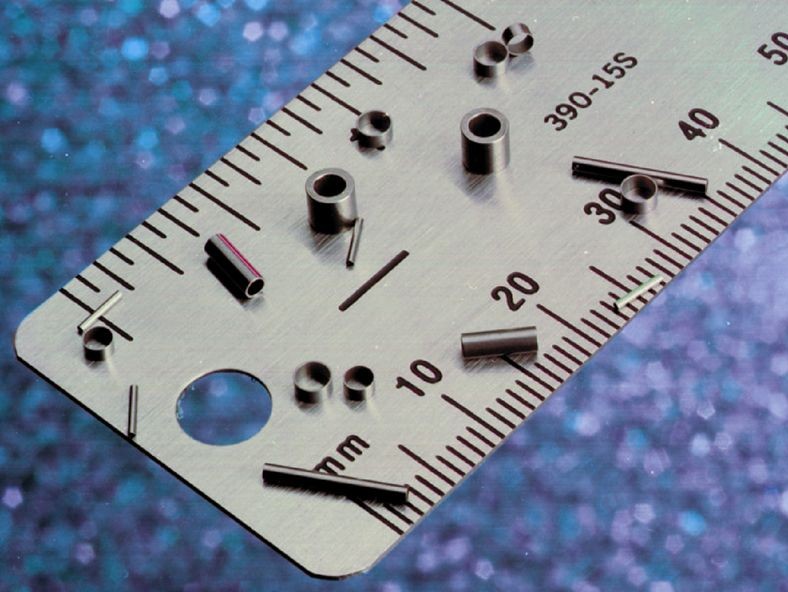

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

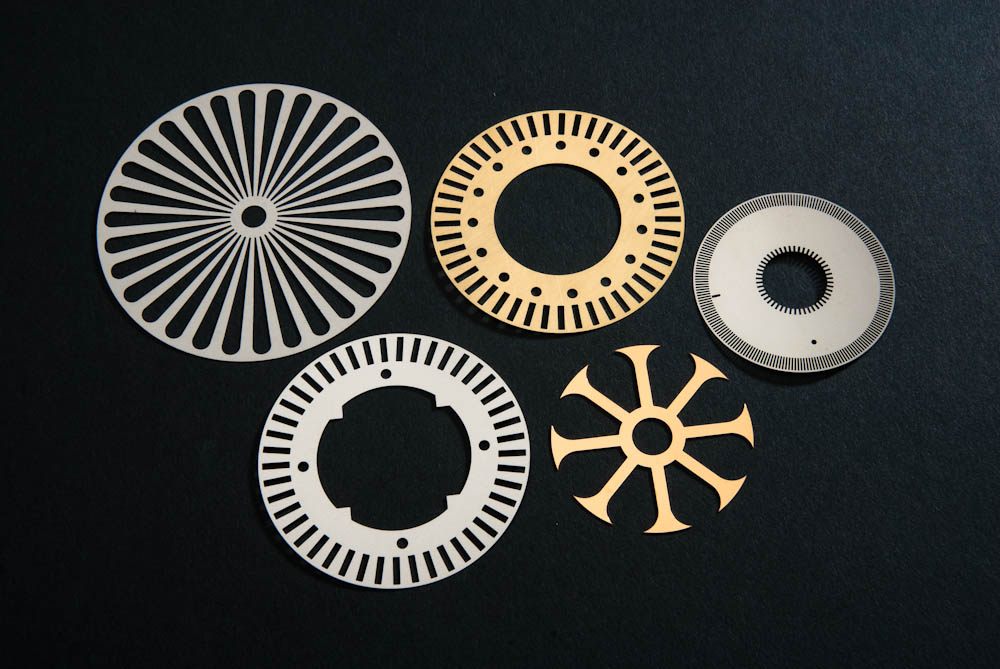

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Photo Engraving Companies

The result is the same; the undeveloped areas of the photoresist protect the metal's surface from being etched, while the developed areas are washed away and exposed to etching agents.

Photo etching and engraving is often used not only on metals, but on glass as well; this technique allows photos or complex images to be engraved rather inexpensively into decorative items.

Like chemical milling and etching, the first step to photo engraving is to clean the metal surface. Next a thin layer of photoresist is laid on the area to be etched. This photoresist protects the metal surface not being engraved but also breaks down under targeted ultraviolet light exposure over the metal surfaces which are to be engraved. The developing process, as with photography, can be reversed; positive or negative working photoresists may be used.

After the photoresist has been applied, the metal is exposed to a precise light pattern. Negative and positive working photoresists achieve different types of images and desired results.

If the photoresist is negative working, the exposed portion will protect the metal while the unexposed portion will dissolve away when chemicals are applied. If the photoresist is positive working, the metal portion exposed to light will dissolve under chemicals while the rest remains.

After the metal has been exposed to a light pattern, a specific chemical will be applied in varying strength and force, again, depending on the desired depth of cut, sideways etch, etc. After the acid has achieved its desired etch, both the ferric chloride and the remaining photoresist are stripped.

The metal is polished, any irregularities in the cut are burnished, and the etching is finished. The benefits of using photo engraving as opposed to regular chemical milling or manual engraving are substantial.

Chemical milling requires parts of the masking to be cut and removed, whereas with photo engraving, the surface merely needs to be exposed to a pattern of light and the photoresist rinsed.

Photo etching allows for much more complex patterns and images to be laid and this is often the only way to etch photos or intricate designs. Photo etching is achieved more quickly and cost-effectively than regular chemical milling.

Broaching

Broaching CNC Machining

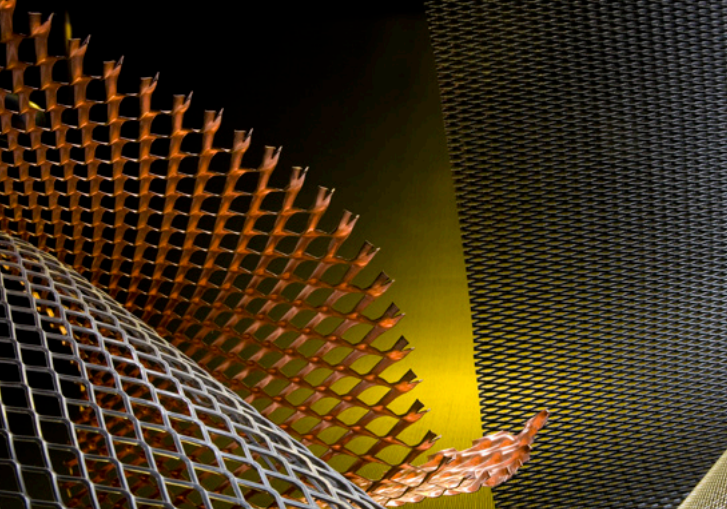

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

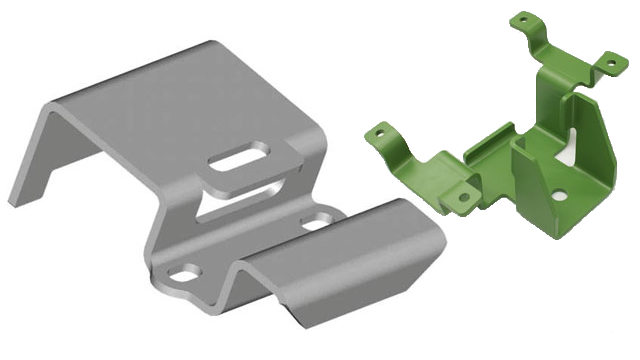

Metal Etching Metal Fabrication

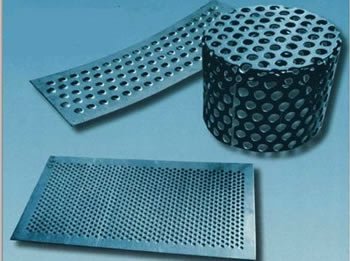

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

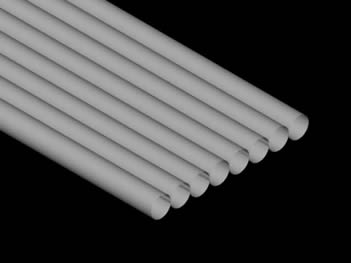

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

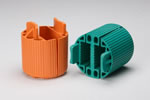

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services