Beryllium copper is a metal alloy that contains 0.4% to 3% beryllium that is alloyed with copper. The combination of the two metals creates a unique combination of metal that is highly conductive and exceptionally strong. A major reason that beryllium copper is used for etching is how easy it is to etch and shape. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Beryllium Copper Etching Companies

The Main Use Of Beryllium Copper Etching

The main use of beryllium copper etching is in the electronics industry for circuit paths and contact points. It can be found on connectors and as a transitional method between two circuit boards. Since beryllium copper becomes stronger as more beryllium is added, it can be adapted to fit a variety of electronic applications.

What is Beryllium Copper Etching?

Though the name etching may offer a vision of using a tool to mark metal, in reality, etching, in the modern era, is a chemical process where various forms of acids are applied to metal to remove unneeded portions of the substrate. The resulting components from the process have excellent strength, conductivity, and endurance. These characteristics are the reason that beryllium copper etching is such a popular and widely used process.

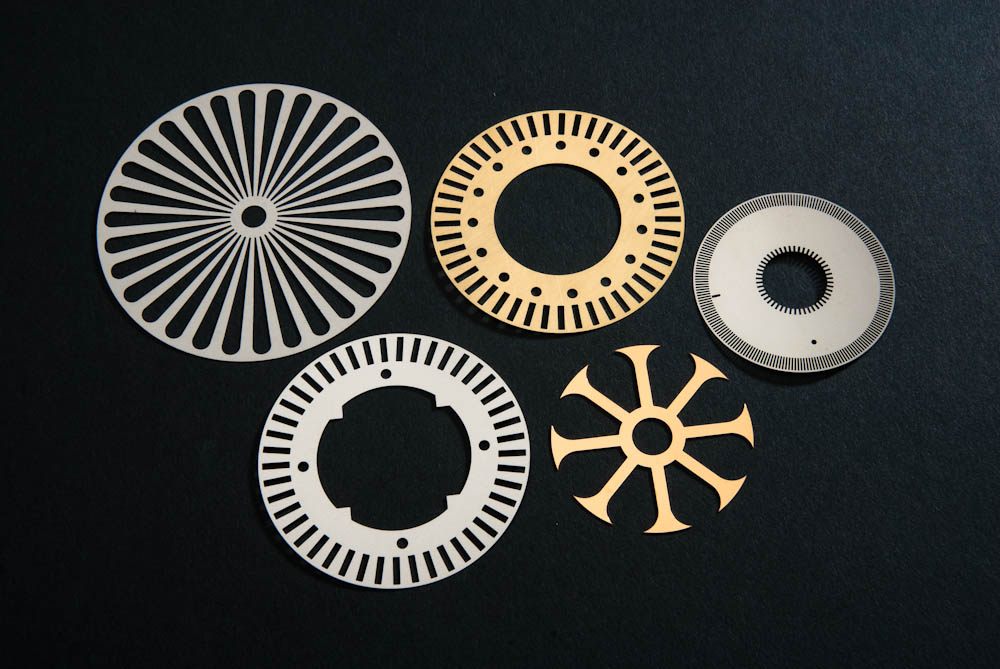

The beryllium copper etching method of production begins with a sheet of beryllium copper, substrate, that is laminated with a light sensitive material, called a photoresist. The laminated sheet is exposed to ultraviolet light to produce a positive image on the metal of the desired configuration. The metal sheet has an etching solution applied that removes the unwanted parts of the substrate.

The precision and delicacy of the process requires that it be monitored during every step. The resulting finished product from beryllium etching has the same and exact diminishes of the original CAD design with exceptional strength. Unlike machining processes, etching does not require the development of molds, tools, or other specialized operations. It is quick, precise, and repeatable.

The Benefits of Beryllium Etching

The results of beryllium etching are complex, multi-layer, extremely precise, and high tolerance parts. The chemical etching process eliminates the need for after finishing processes such as deburring, buffing, or shaping. All aspects of the final beryllium copper etching part are completed such that it is ready for its next application.

Unlike machining, where metal has to be stressed and shaped by force, beryllium copper etching does not require such aggressive methods. When a part is removed from the process, it has the same mechanical properties it had when it was first laminated. The lack of stress ensures that the metal retains all of its characteristics and properties.

As with all etching, beryllium copper etching does not require special tooling, set up, or other unique processes. All that is required is a CAD driven design that can be placed on a sheet of beryllium copper using photoresist material. Once these requirements are met, the production of the final part begins.

Applications for Beryllium Copper Etching

Due to beryllium copper being the strongest of the copper alloys, it has become extremely popular in several industrial applications. The area where beryllium copper is used the most is in electronics where it is utilized as connectors, pins, and terminals.

In plastic and metal mold production, beryllium copper etching creates inserts for the injection molds. When it is used for inserts in plastic molding, it reduces the heat and nearly eliminates the need for water cooling. The thermal conductivity of beryllium copper etching inserts is four times better than steel molds.

One of the problems with computers is their vulnerability to electromagnetic field interference (EMI) and radio frequency interference (RFI), which can damage or ruin computer components. The mechanical and electrical properties of beryllium copper etchings make them ideal for use as EMI and RFI shields.

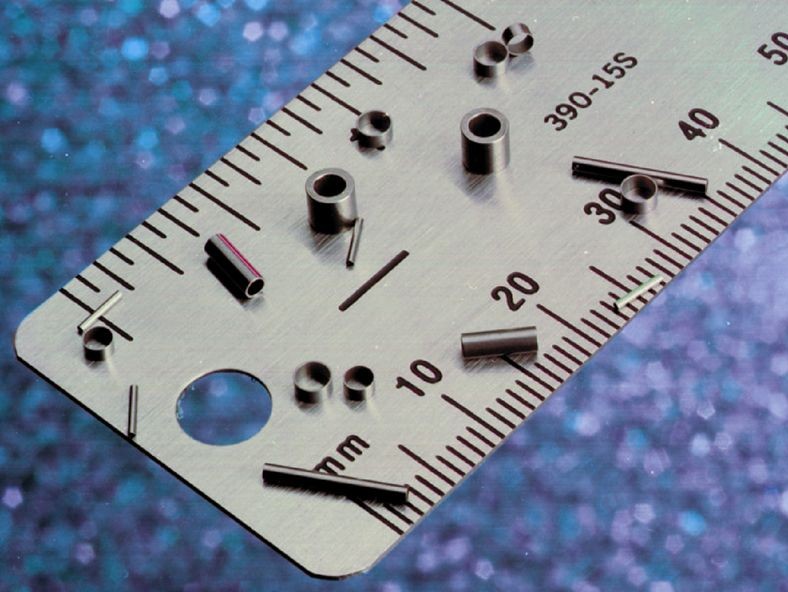

A growing area in electronics is microelectronics where extremely small, delicate, and intricate parts are required that need to be durable enough to withstand constant use. The ability of beryllium copper etching to create these small parts using high precision and exceptionally accurate processes enables engineers to create designs that require thin and tiny surfaces.

Broaching

Broaching CNC Machining

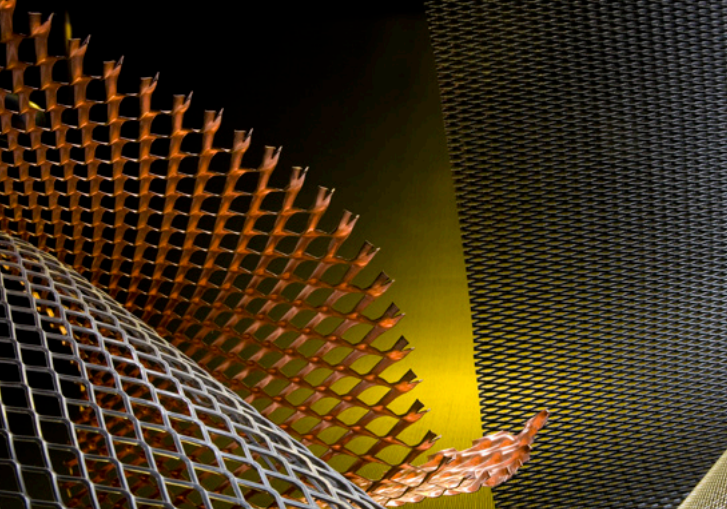

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

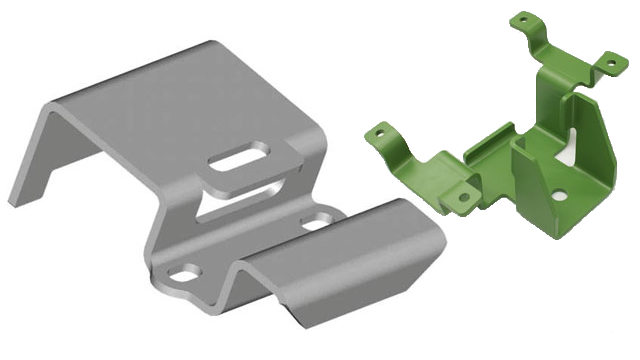

Metal Etching Metal Fabrication

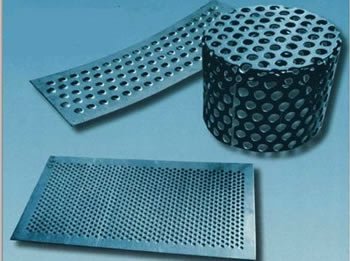

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

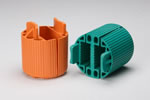

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services