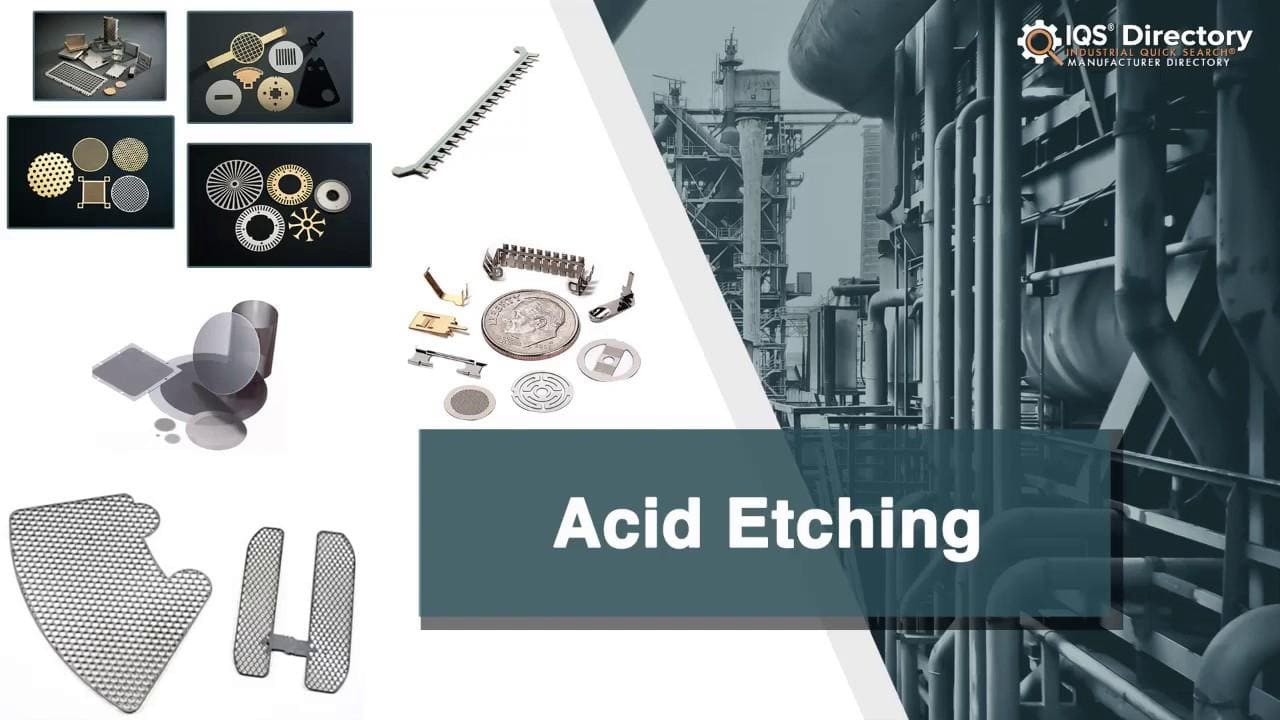

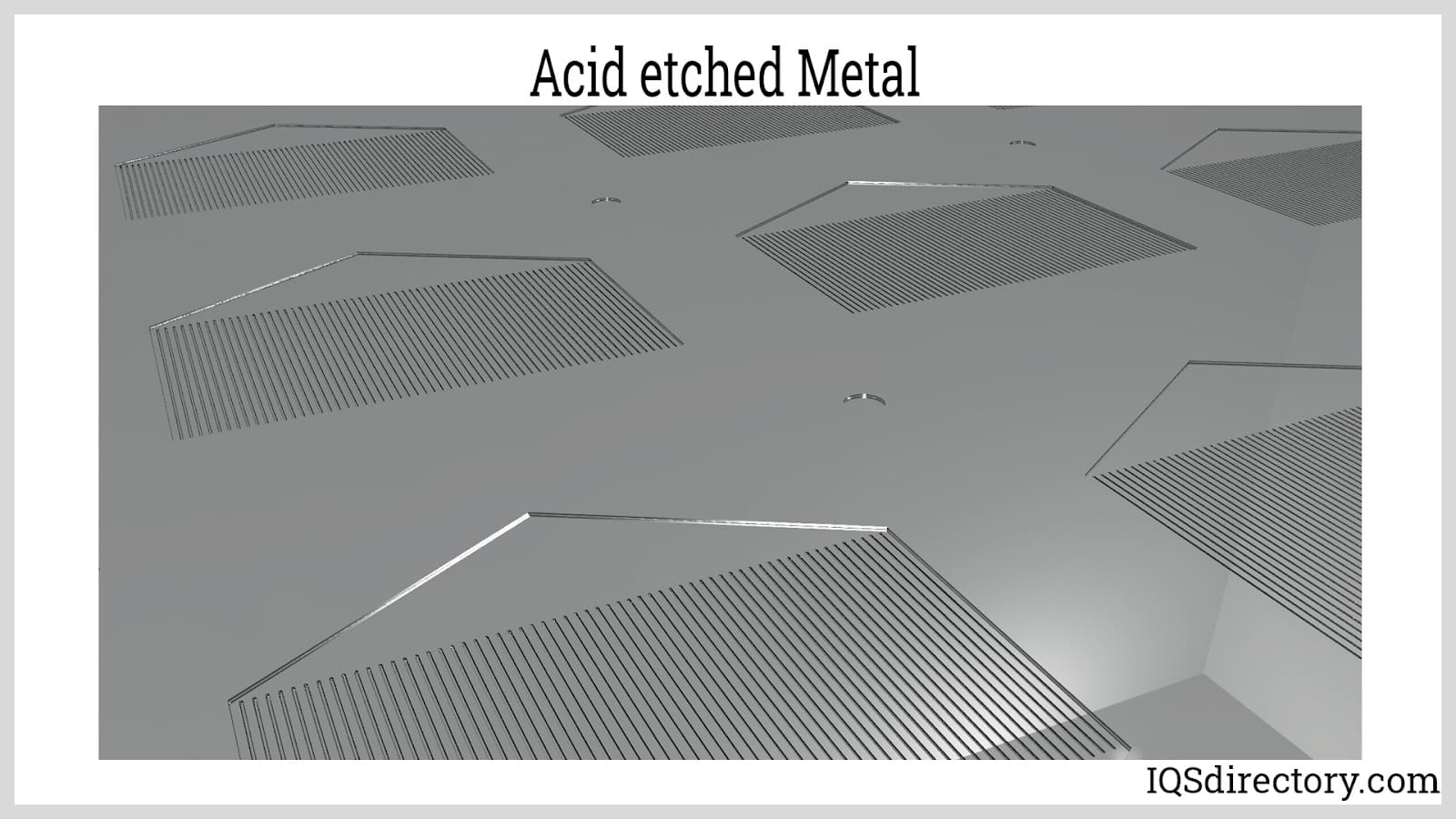

Acid etching is a process where a hard metal is cut using a specially formulated acid to allow the formation of the desired design onto the metal. The acid etching process uses mordant acids that are available together with chemical compounds to impart a physical or aesthetic improvement to the metal surface. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

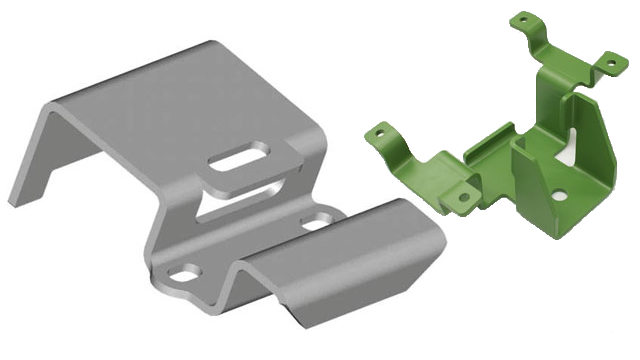

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Acid Etching Companies

Acids Used in Acid Etching

Many types of acids are used in etching stainless steel, including sulphuric acid and nitric acid. These acids all require proper and careful handling. The acids can dissolve fingers or stainless steel. A faster etching process is usually the result of a stronger acid.

Hydrochloric acid is mostly used during copper etching. In the etching of mild steels, copper sulfate is used. Nitric acid is best used in a one-to-three ratio with water.

Metals That Can be Acid Etched

Any known metals can be etched with acid, the most popular being attractive metals due to their characteristics and properties. Metals that are used mostly in acid etching are listed below:

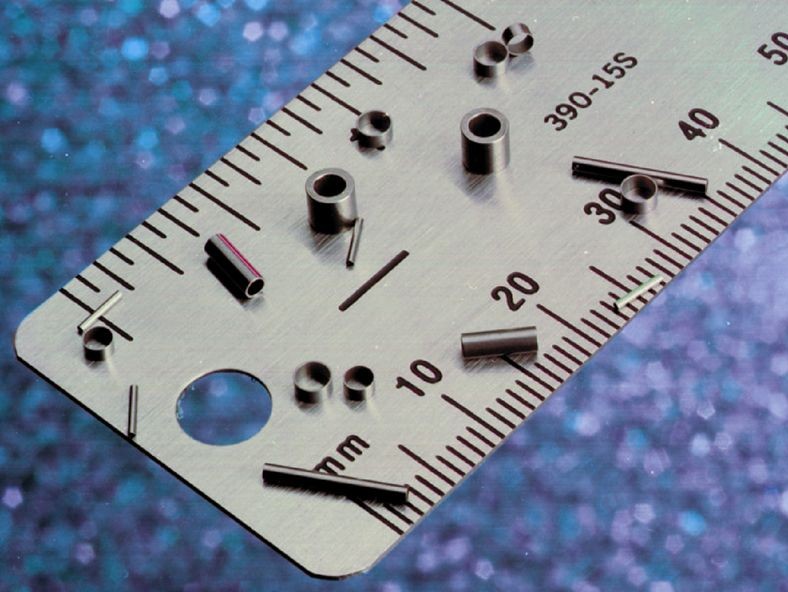

Titanium – Titanium is a strong, lightweight metal that possesses good fatigue characteristics.

Aluminum – Aluminum is another strong and lightweight metal with good corrosion resistance and weight ratio.

Copper – Copper is a soft metal that etches very quickly.

Nickel – Nickel is resistant to extreme temperatures and usually used as an alloy.

Stainless Steel – Stainless steel is very resistant to corrosion.

Bronze – Bronze is a ductile metal. It is very firm, stiff, and hard compared to copper.

Molybdenum – This metal has high strength characteristics and good electrical conductivity. Molybdenum is known for its high thermal properties and low thermal expansion.

Types of Acid Etchings

The types of acid etchings include:

Steel Etching

The requirements for steel etching are distilled water, acetone, plastic container, rubber gloves, ferric chloride, wet-steel wool, etch resist, and dental paper. The most important part is the preparation of these etching components. Poor preparation will give a disappointing outcome.

The initial stage of preparation involves dissembling the knife, where there should be no amount of acid on the liners, scales, or washers. Afterward, the blade is cleaned with acetone. This process creates a very clean surface so that the etch resist will adhere to it quickly.

The third stage involves the creation of the etch resist pattern. The pattern is formed on the steel as a barrier is created to stop the acid before it reaches the steel. A pattern forms when the resistance is removed, and all the exposed metal is darkened and marked by the acid.

Following this step, the etch acid is mixed before the etching starts. This mixing must be done in a well-ventilated area. There are two main processes of acid etching: acid bath etching and focused etching. Sanding, stone washing, and clean-up follow before the final results are obtained.

Aluminum Etching

Aluminum etching is considered a less toxic, simple, cheap, and safer kind of metal etching. The general steps in aluminum etching start with the preparation of the mordant. Next, copper sulfate is dissolved with salt, and the solution is allowed to cool. Copper sulfate is toxic in large quantities.

The etch must always be allowed to cool before use since it can produce an aggressive smoke during etching. However, the process is quick to finish, and interesting textures can be obtained if coarse salt is used.

Applications and Benefits of Acid Etching

The applications and benefits of acid etching include:

Applications and Uses of Acid Etching

The applications of acid etching are broad, and listed below are some of the areas they cover:

- Lead frames

- Contacts and electrical connectors

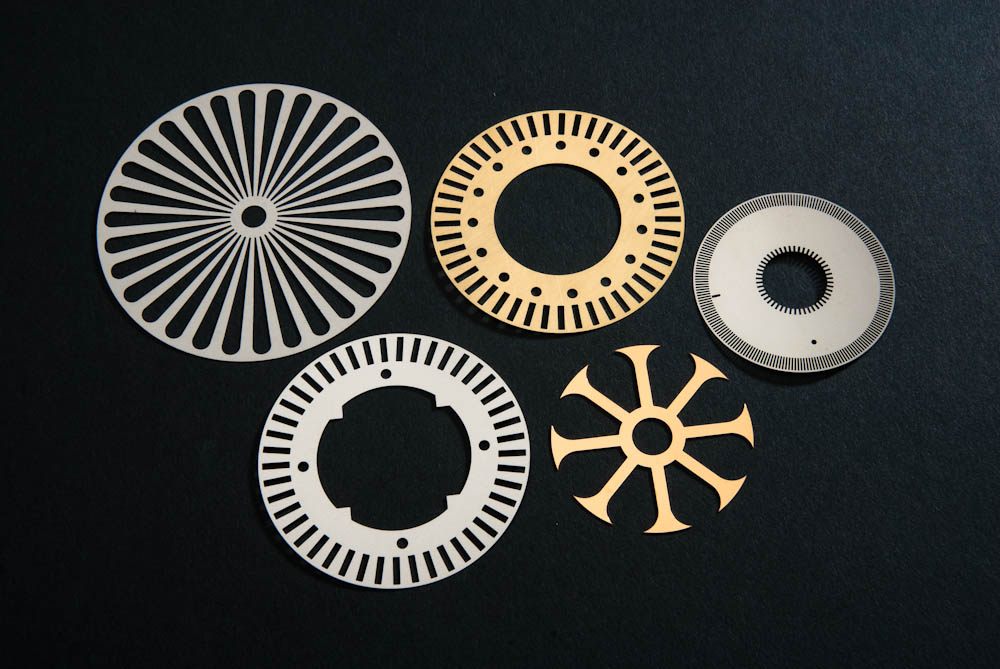

- Motor laminations

- Medical instruments and devices

- Plate heat exchangers

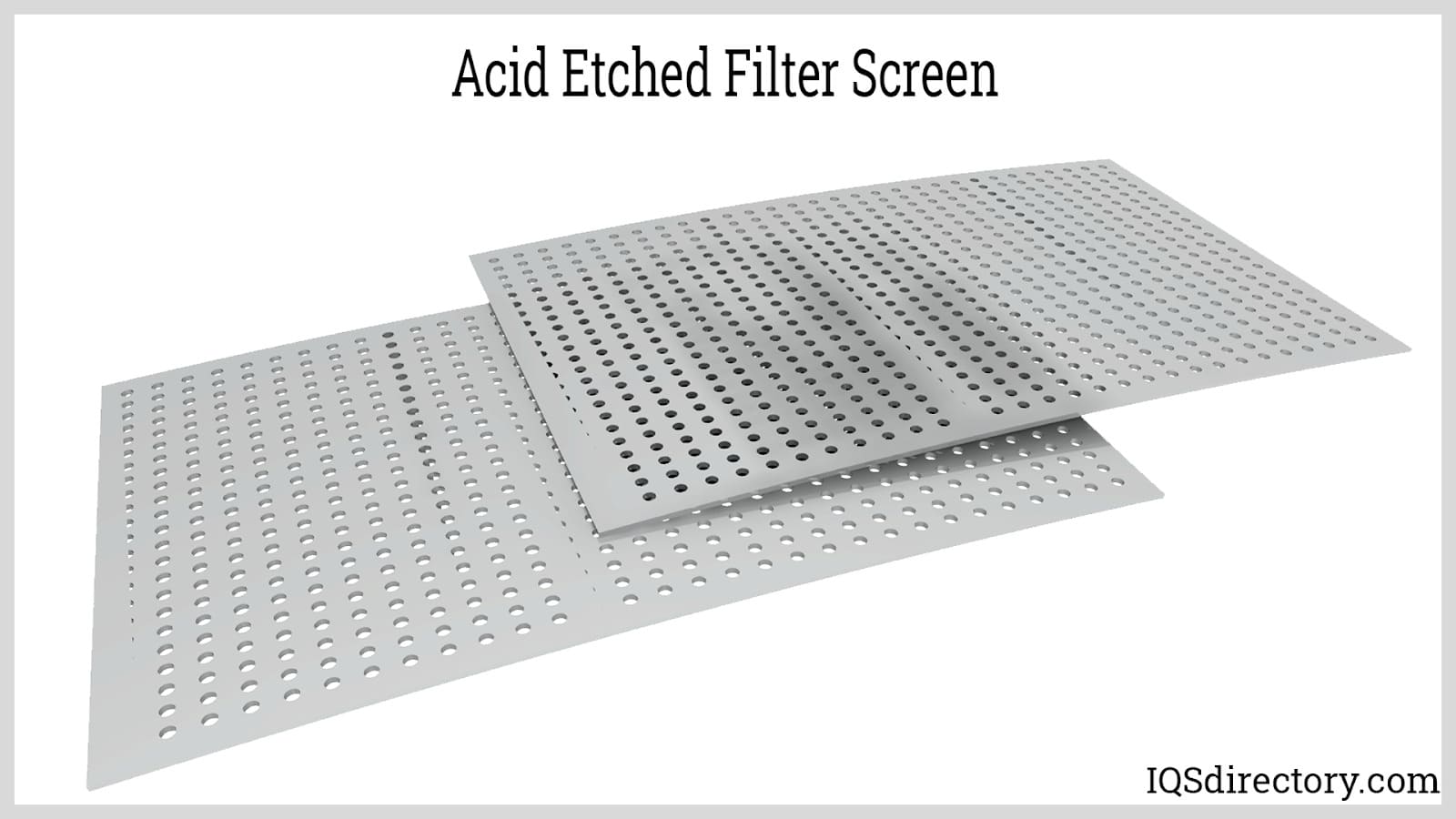

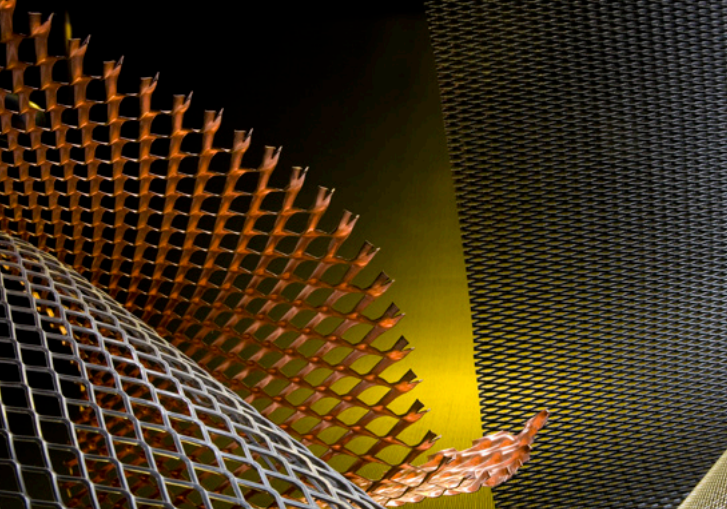

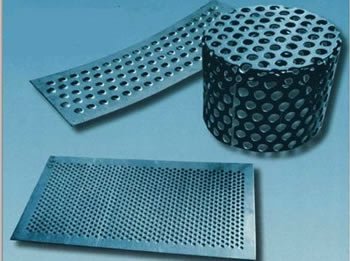

- Filters, meshes, and sieves

- Gaskets, washers, and shims

- Cranio maxillofacial implants

Benefits of Acid Etching

- Little or no hard tooling is required

- Unlimited complexity

- Low cost

- Fast iterations

- High accuracy

- The metal's properties are unaffected

Choosing the Right Acid Etching Company

To make sure you have the most productive outcome when purchasing Acid Etching from an Acid Etching Manufacturer, it is important to compare at least 4 or 5 Companies using our list of Acid Etching suppliers. Each Acid Etching Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Acid Etching company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Acid Etching companies with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services