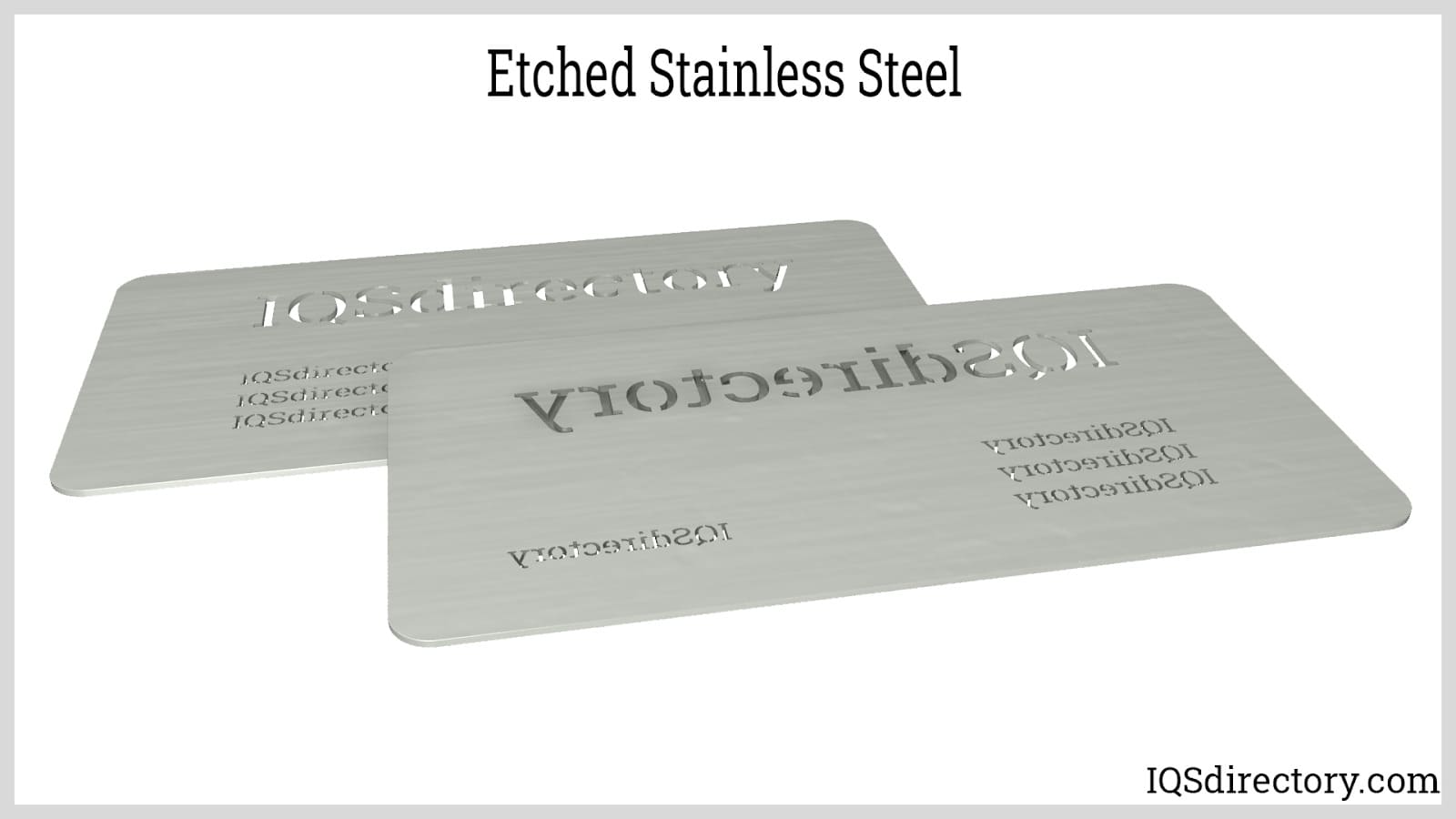

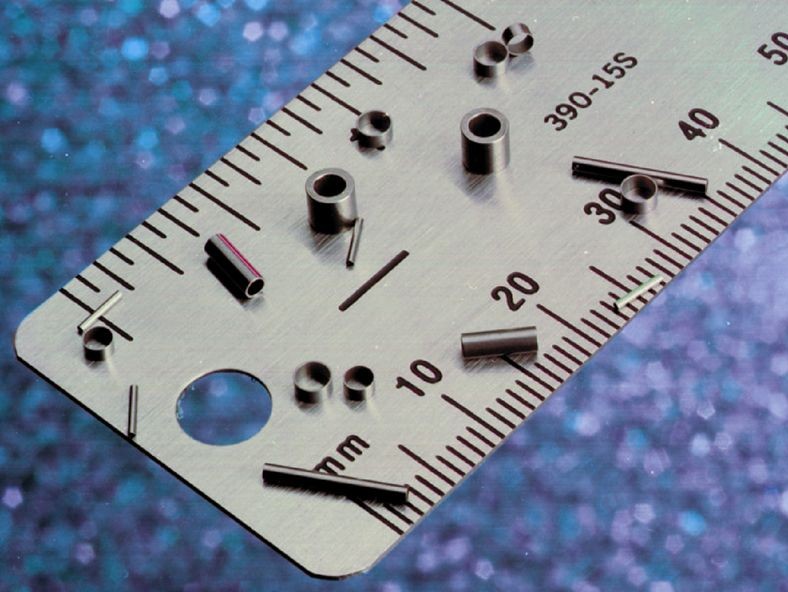

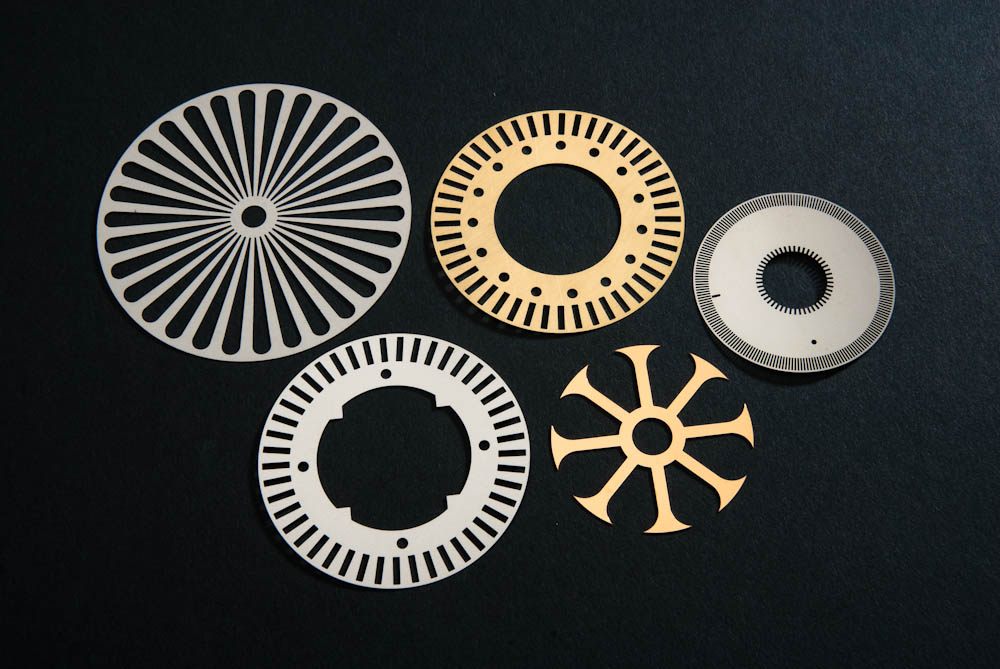

Stainless steel etching refers to a specialized metal etching process that uses corrosive chemicals to etch complex shapes from sheets of stainless steel. The process of stainless steel etching is a highly accurate process that results in more complex parts with no mechanical stress placed on the material. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

Photochemical machining is the process we use on aluminum (and alloys), brass, copper, inconels, kovar, metal foils (less than .001” thick), metal sheets (up to .125” thick), mild steels, molybdenum, monels, nickel, phosphor bronze, stainless (300 & 400) and others. Trust your metal etching needs to us.

More Stainless Steel Etching Companies

Stainless steel is an excellent material for laser etching since images placed on it can meet the photo quality standards. In addition, stainless steel can easily accept the photo-resistant laminate mask and the CAD image as experienced in photochemical etching.

The ferric chloride removes the unnecessary metal from components as it does other metals. The process of metal etching is commonly used in producing stainless steel parts because burrs are not produced, and the metal is not stressed.

Grinding and milling machines are also used to achieve certain etching finishes on stainless steel. These are used especially on stainless steel sheeting used for larger decorative purposes.

How Stainless Steel Etching Functions

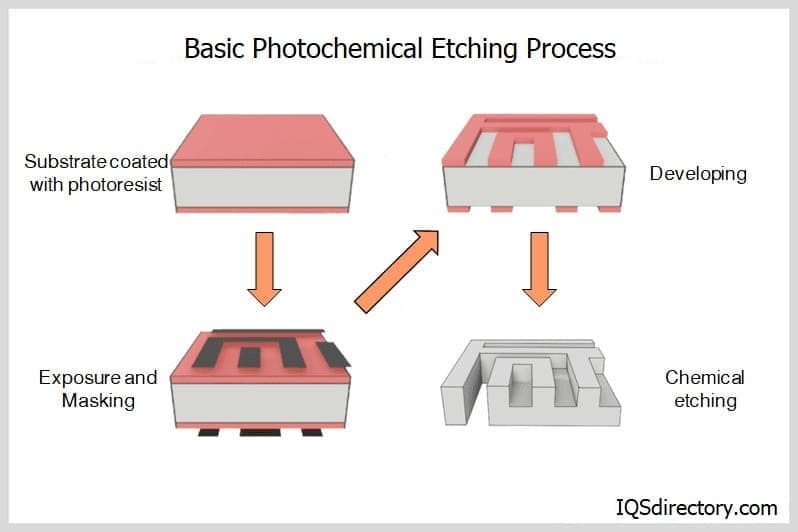

This process starts with metal being laminated with a light-sensitive photo-resist exposed to UV light to transfer the CAD image of the component. The areas of unexposed photo-resist are then removed and sprayed with etchant chemistry. Finally, the remaining photoresist is stripped to reveal the final etched component.

Types of Stainless Steel Etching

The type of stainless steel etching is determined by the technique used to remove metal from the surface of the substrate. Three etchants may be used for the stainless steel etching process. These are electrolysis processes for electro etching, acidic chemical etchants for chemical etching, and high energy density laser for laser etching.

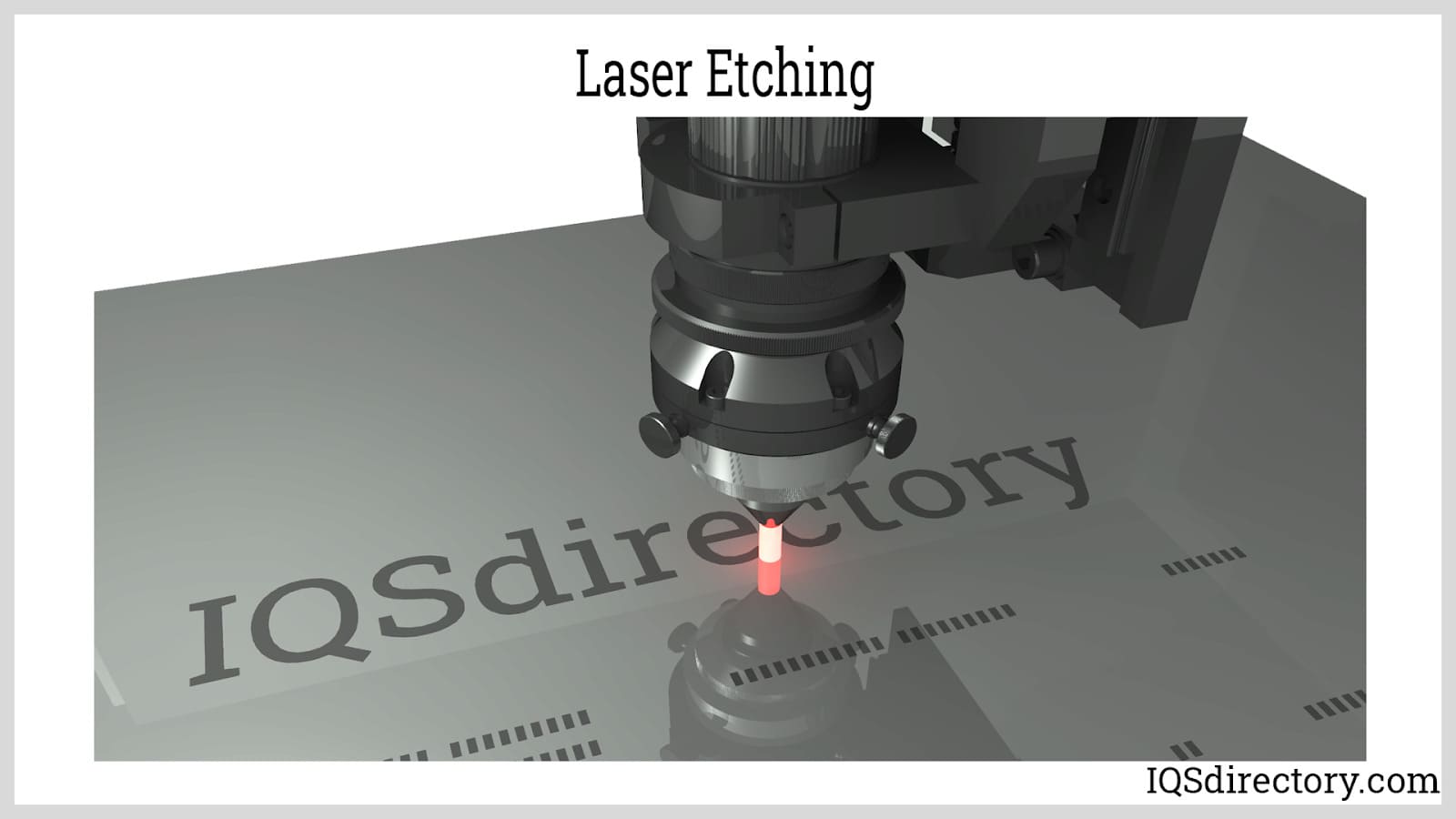

Laser Etching

Stainless steel etching uses high energy density laser light in its function. This light is focused on the area being engraved while ensuring that the surrounding area is not affected. The high-density laser hits the metal surface; some light reflects off, but the metal absorbs the rest in the form of heat. By doing so, the laser light heats the metal and melts away the hit part.

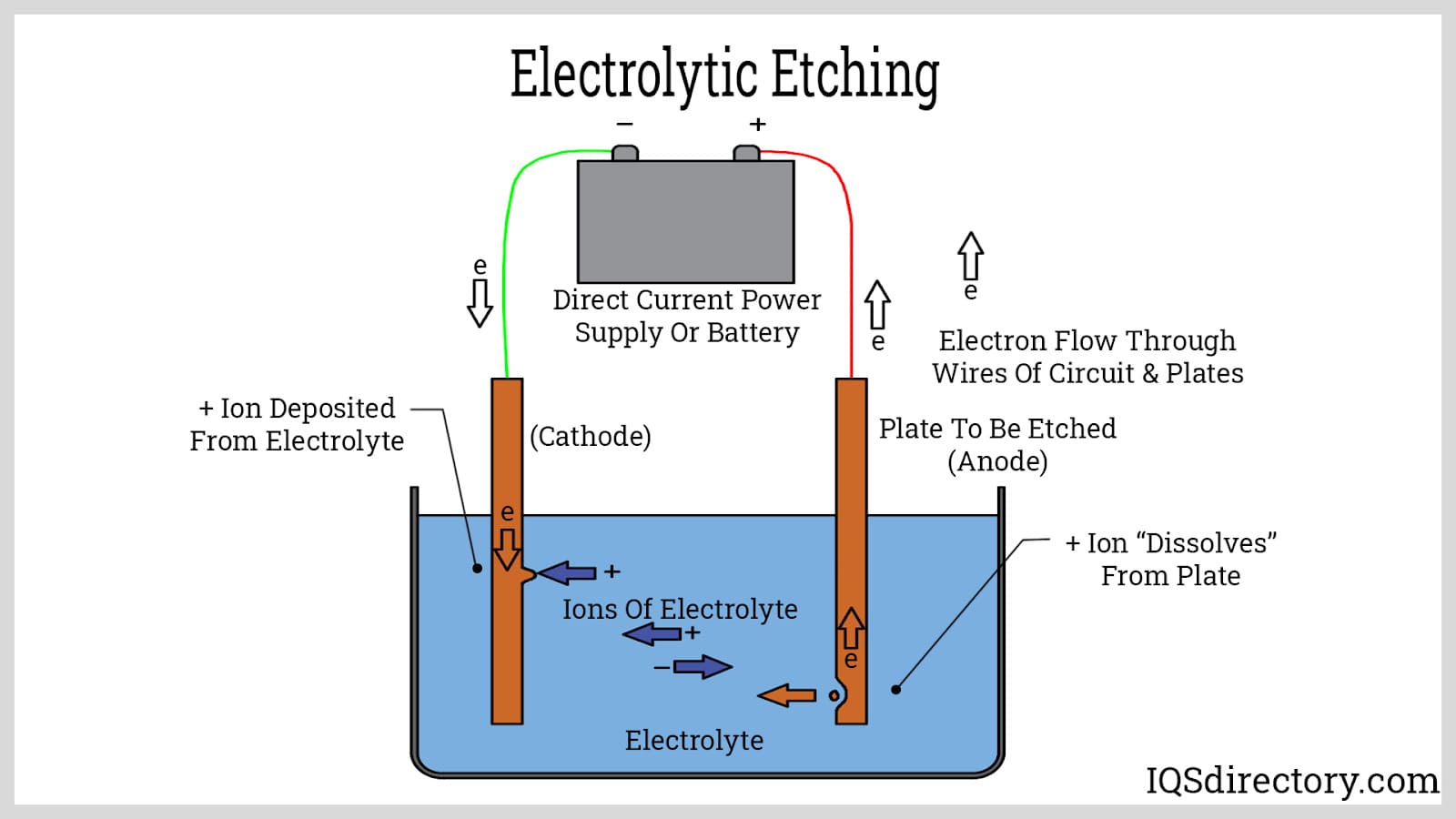

Electrolytic Etching

This process is also known as electrochemical etching. It uses electricity and leaves permanent engravings on the metal. The main contributors in the process include the anode, cathode, and chemical electrolyte. The part to be etched is connected to the positive pole of a DC source. The other part is connected to the negative terminal of the DC source. When the switch is turned on, the current can pass from the anode to the cathode via the electrolyte where the metal is dipped. The cations obtained from the anode will discharge and deposit on the cathode. Depleting the anode side leads to the creation of a surface etched on the metal.

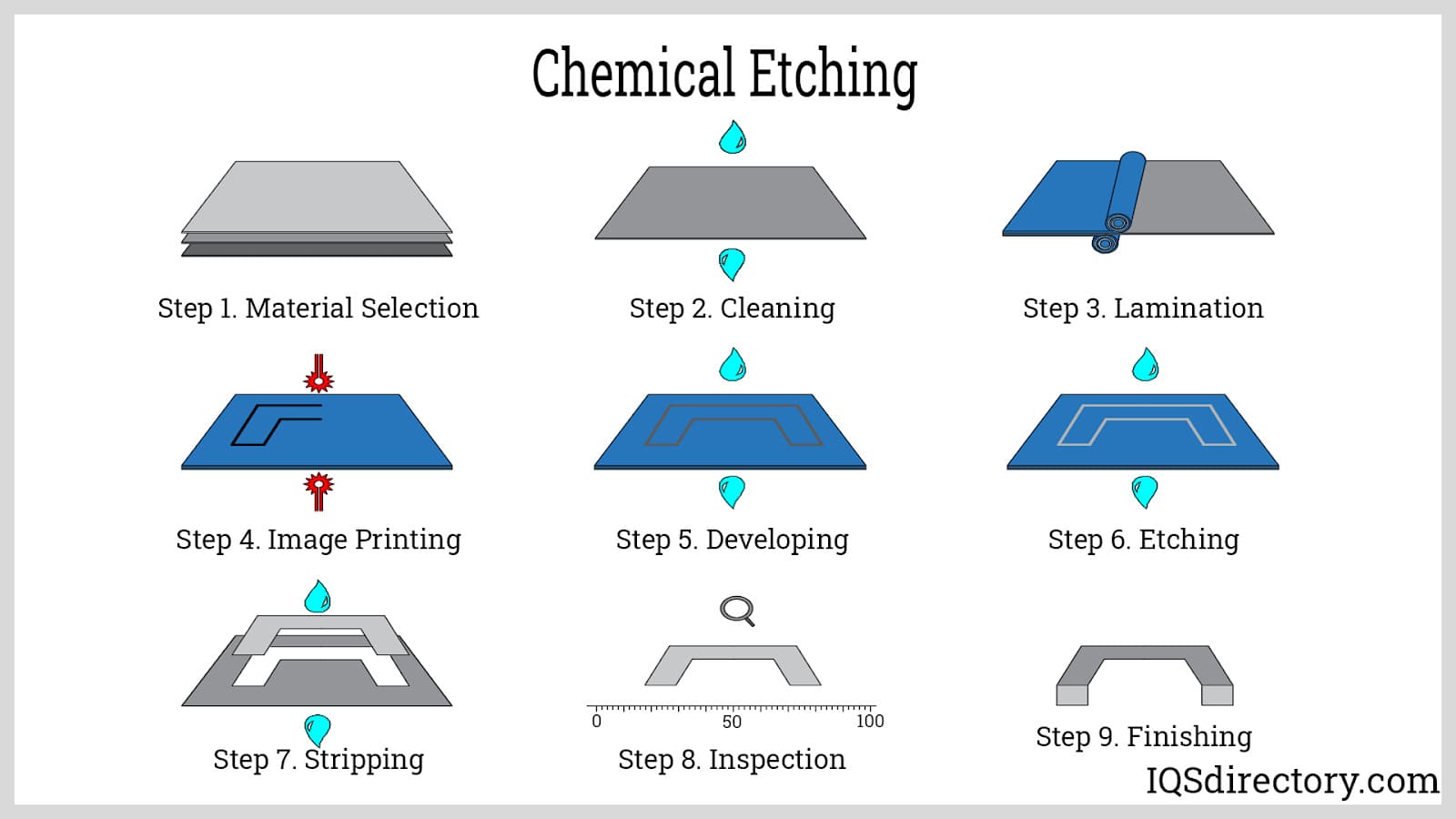

Chemical Etching

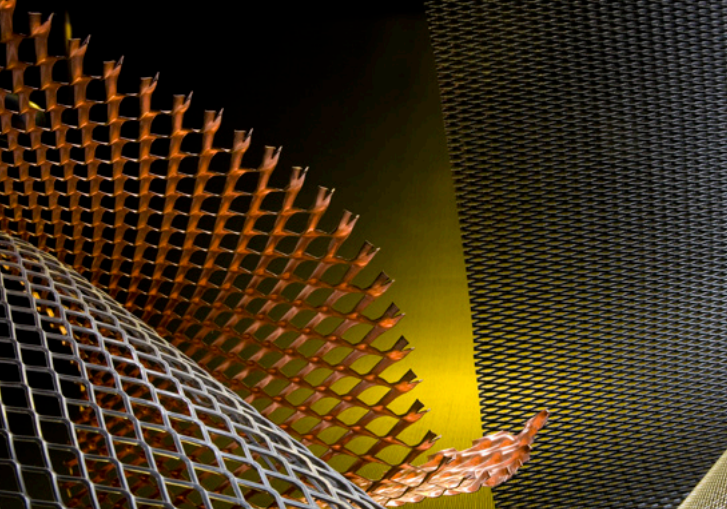

Chemical etching uses an acidic chemical that can etch off the surface it acts on. Acid metal etching is performed in an acid bath, dipping, or flow coating. The metal type to be etched affects the acid etching process because some metals etch quicker than others. Hydrochloric acid, nitric acid, and sulphuric acid are mostly used for chemical etching.

Photochemical Etching

The process of photochemical etching uses chemicals and light to remove material. The photochemical etching process begins with the creation of a design using CAD. Once this is finished, the thickness of the metal is determined as well as the number of pieces that will fit on a sheet.

Applications and Uses of Stainless Steel Etching

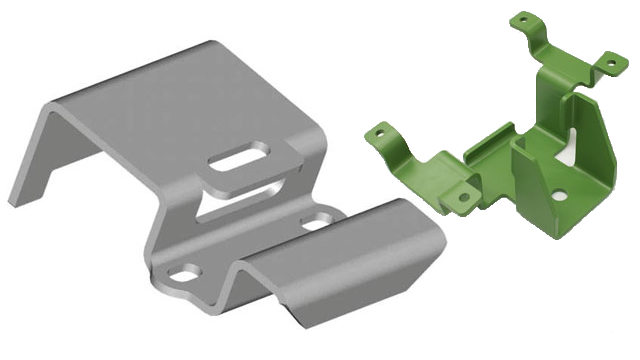

Stainless steel is chosen in most industries because of its strength, smooth tarnish-free surface, formability, and resistance to corrosion. For example, stainless steel etching is found in the aerospace and automotive industries because of the need for strength and corrosion resistance in producing engine parts such as fuel cell plates.

Stainless steel is required in these engines because it avoids material breakdown in engines that contact gasses and liquids. Stainless steel is also used in parts such as gaskets and shims that must be able to withstand force, heat, and friction for safety standards.

The smooth, clean surface is a prominent feature for automotive speaker grills, medical instruments, and interior inlays that must be sanitized without the threat of material breakdown. In addition, stainless steel step lids and RFI/EMI shielding can be plated to enhance many electronic products. Decorative works on jewelry, firearms, plaques, medals, trophies, and musical instruments also use stainless steel etching.

Choosing the Correct Stainless Steel Etching Company

To make sure you have the most beneficial outcome when purchasing Stainless Steel Etching from a Stainless Steel Etching Supplier, it is important to compare at least 4 Suppliers using our Stainless Steel Etching directory. Each Stainless Steel Etching Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Stainless Steel Etching company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Stainless Steel Etching companies with the same quote.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

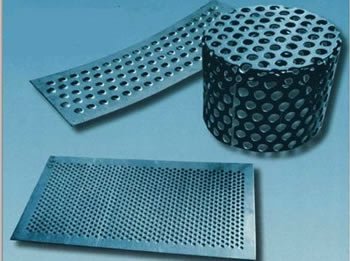

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services