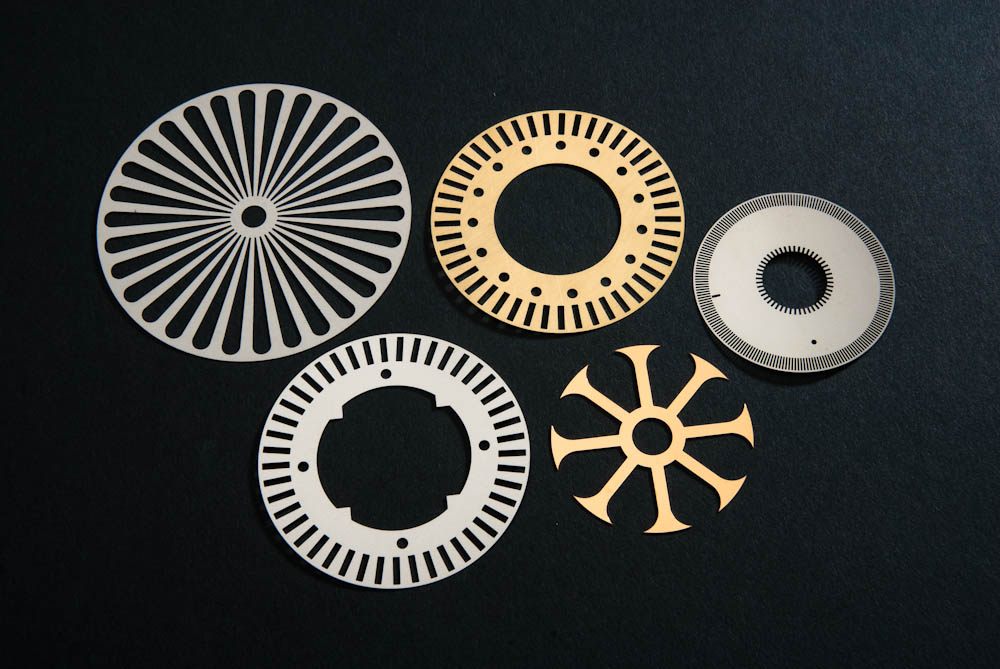

Metal etching, or metal engraving, is a method of creating impressed designs, grooves or fine lines on metal parts and sheets. Metal etching services are used for a wide variety of decorative and industrial applications. Decorative etching applications include jewelry design, musical instrument decoration, firearm engraving, plaque and trophy decoration and engraving and architectural and furniture embellishments. Read More…

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

At Bazzill Engraving, we do personalized, industrial, custom, metal engraving and plastic engravings. Common materials that we use are hardened metals, stainless steel, aluminum, brass, copper, bronze and many others. For over 34 years we’ve been serving the southern Arizona valley, so contact us today for guaranteed success!

When it comes to engraving services, Engrave It Houston gets it done quickly and efficiently. As the premier source for custom engraving our dedicated staff will work with you every step of the way. We use state of the art equipment for a number of services including sand blasting, screen printing, rotary engraving and chemical etching. Visit our website for more information.

Metal Craft provides CNC machining services for medical, computer and aerospace industries. We strive to exceed customer expectations of quality, service and innovation. Whether you require CNC milling, grinding, turning or many other processes, skilled professionals guide you from start to finish. We also do laser etching and passivation.

More Metal Etching Companies

In decorative metal etching, surfaces are sometimes smoked to make lines appear more visible.

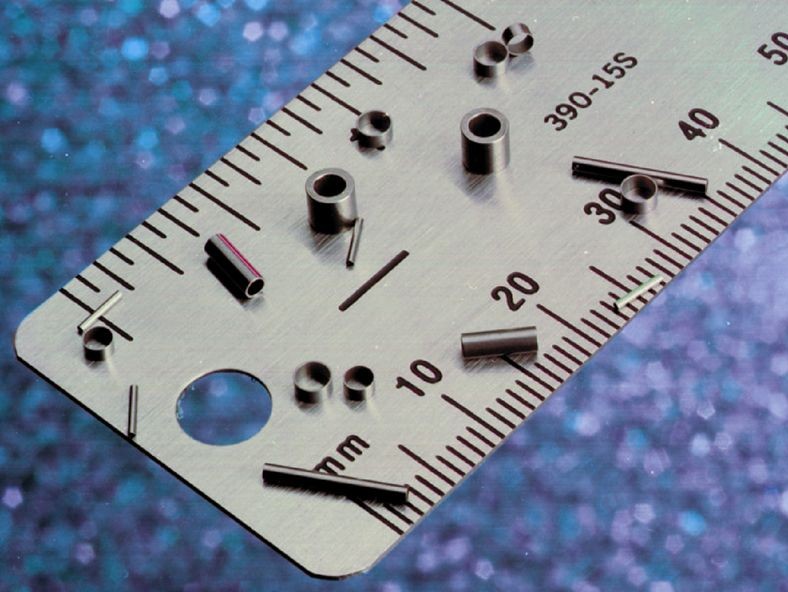

Industrial applications for etching include: stenciling, plate printing and foil-stamping dies. Etching helps manufacturers fill their various precision part requirements, and also comes in handy in the medical field, which uses metal etching and chemical machining in order to get the right finish on devices like stents, cathodes and implants.

Finally, this highly versatile process is a suitable for creating intricate parts and devices for the aerospace, electronics and defense industries; metal etching helps make printed circuit boards, engraved missile skin panels and jet frames.

History

The metal etching process was traditionally completed by hand, using a fine tipped tool, like a burin. Hand etching always creates unique patterns, however, due to its time-consuming nature and inconsistency, it was eventually largely replaced with other techniques.

Etching has been a well-known technique since the Middle Ages, though it’s likely it’s been going on since before then. Etching was performed on soft metals like zinc and copper, then later on stronger metals, such as steel. Some of the best examples of medieval metal etched products we have today are 16th century armor, cups, plates and guns.

The aforementioned 16th century was an important time for metal etching. In the mid-early 1500s, a German craftsman named Daniel Hopfer invented the process as applied to printmaking. The printmaking process at the time involved plates, wax and an acid. It went like this: Craftspeople would cover the plates in acid resistant wax, then scrape the wax away and expose the metal in order to create a printing die with a pointed etching needle. After carefully scraping away all of the wax they wanted, they’d bathe the plate in an acid. The acid would dissolve the exposed metal, leaving behind sunken lines and words. The resulting metal plates were then inked and used for printing purposes.

Using iron plates, Hopfer applied this method to decorate armor. Two examples of his etched armor work still exist today—a sword in the Germanisches Nationalmuseum of Nuremberg and a 1536 shield in the Real Armeria of Madrid. The German Historical Museum in Berlin also houses an Augsburg horse armor decorated with images from Hopfer’s etchings. There is, however, no evidence that Hopfer himself decorated this armor. It dates between 1512 and 1515. In addition, many of his plates are still in existence in museums.

After Hopfer’s innovation, metal etching soon replaced metal engraving. Metalworkers quickly began using chemical etching to etch trajectory information onto canons and artilleries, and decorate shovels, stiletto daggers and all kinds of equipment.

In the 18th century, John Senebier, a Swiss botanist, astutely observed that some plant resins, once exposed to light, hardened and became insoluble to turpentine. This observation led first to the development of photography, then photochemical etching. In early photo etching, they applied a liquid acid-resistant resin to a metal, then exposed it to light. The light etched an outline around the masked area. At the time, this photo etch method was used to make metal plates. Modern photochemical machining entered commercial use in 1927 when a Swedish company, Aktiebolaget Separator, began using it to produce edge filters. Not long later, they patented it for cutting gap filters. The method gained popularity around the start of World War II, when people began etching much harder metals. Photochemical machining allowed them etch metal from both sides and to create sheet foil etched parts.

Since the mid-1900s, metal etching technology has evolved significantly. Most of modern etching works using the same principles and components it always has, but with the addition of different maskants and etchants and CNC technology. Modern etching can also make use of lasers and electromagnetic discharges.

Materials Process

The metals most commonly etched are aluminum, copper, stainless steel, nickel and brass. Engraving machines may also service surfaces like glass and plastic.

Aluminum

Aluminum is another naturally occurring element know for: durability, softness, oxide resistance, corrosion resistance, ductility, recyclability and lightness.

Copper

Copper is another naturally occurring element. Unlike most elements, it is found in nature in its metallic form. Copper offers many useful characteristics, including: softness, malleability, ductility, thermal conductivity and electrical conductivity. Because it has so many desirable properties, it is a component of many alloys, including brass, nickel silver and bronze.

Stainless Steel

Stainless steel is a steel alloy, made up of no less than 10.5% chromium by mass. Stainless steel is extremely popular, and for good reason. It is corrosion resistant, oxidation resistant, hypoallergenic and extremely strong and durable.

Nickel

Nickel is a transition metal with the chemical symbol Ni. It is ductile, hard, lustrous, strong and corrosion resistance.

Brass

Brass is a copper-zinc alloy. It is known for its high malleability, low melting point, castability and antimicrobial effect on microorganisms and pathogens.

Process Details

1. Clean surface

Before doing anything else, you need to clean the etching surface with a deoxidizing or alkaline solvent solution. By cleaning the surface, you ensure that it is free from contaminants like oils, primer coatings, grease and metal marker residue. This is important because contaminants can alter chemical reactions and create inconsistent etching results.

2. Apply maskant

During this step, you apply a masking agent to the workpiece in a predetermined pattern. You can apply the maskant either by immersing the parts in it (dip masking), or by letting it flow over them (flow coating). Industrial maskants are usually polymers or elastomers of some sort, such as isobutylene-isoprene copolymers or neoprene elastomers. Choose these for their ability to retain their structural integrity during chemical reactions.

3. Immerse in etchant

Next, you etch the metal by immersing it into your etchant, which is a corrosive material like ferric chloride. Where the metal is not protected by the mask, it will experience the chemical reaction that creates etchings. Leave the parts in the tank for as long as required.

4. Remove the maskant

Now you demask the product, or remove the maskant and etchant. Typically, you remove the maskant manually with scraping tools. To remove the etchant, you usually immerse it in a cold-water bath or a specialized bath, such a deoxidizing bath.

5. Finishing

After etching, manufacturers can smooth or polish away any imperfections, burrs or marks.

Design

When designing a metal etched part, manufacturers plan out details like: depth of cuts and etch patterns. To get the results they want, manufacturers then plan out: the material they will use, the etchant composition, the etchant concentration, the rate of etching (the ratio of the depth of the cut to time spent in the bath) how long the metal will remain in the etchant (for a deep etch, they’ll leave it in longer) and the temperature. Common etchants include: ferric nitrate, ferric chloride (best for copper or zinc), nitric acid (best for zinc or steel), copper sulfate, HNO, hydrochloric acid and citric acid. To make sure that they’ve got it right, manufacturers will usually do a test run.

Machinery Used

Fine Tip Lathe and CNC Controls

Mechanical milling uses either a lathe or CNC machine with fine tips that can process a range of materials and dimensions, including straight or curved surfaces. The associated computer controls the cutter’s direction, pressure and speed, which produces a precise, repeatable image or design with clean, fine lines.

Milling and Grinding Machines

Milling and grinding machines can also achieve certain finishes on large metal sheets used for decorative or furniture applications. Though they consistently produce high quality work, the initial tooling costs of these techniques are high, and maintenance requires trained personnel.

Hand Engraving Equipment

For more smaller and more intricate projects, especially decorative ones, some manufacturers still use hand engraving equipment. This equipment consists of three components: a stylus or marking tool, a controller and surface. The stylus is usually made with diamonds, so that it can metal engrave even the hardest surfaces.

Variations and Similar Processes

Chemical Milling

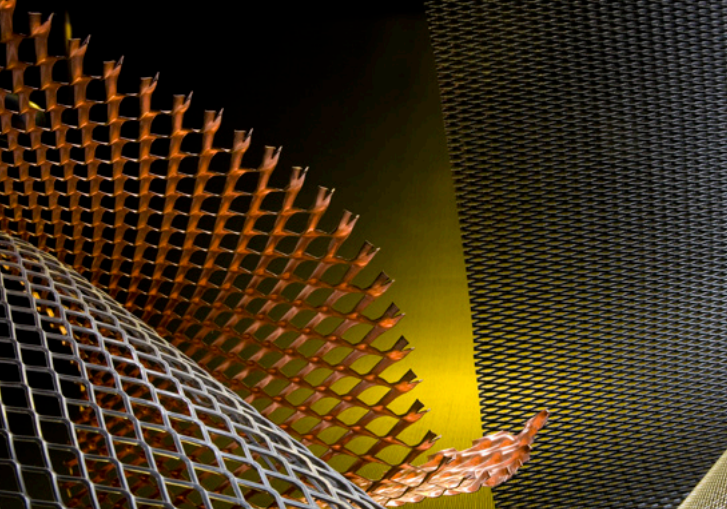

Chemical milling, also known as photochemical milling or chemical machining, also involves a masking compound and an etchant. During chemical milling, manufacturers start by covering a piece of sheet metal in an inert masking compound. Then, they bathe the metal in an appropriate etchant. As the exposed metal and etchant react, the etchant cuts via dissolution.

Mechanical Milling

Mechanical milling is used to etch a wide range of metal surfaces, both straight and curved. With the help of CNC controls, the cutter or laser moves carefully and prescribed speeds, applying precise pressure. This creates designs and images with fine, clean lines. The only drawback of chemical milling is that it has high initial tooling costs and you must perform maintenance on it using qualified personnel.

Acid Etching

Acid etching is quite a bit like chemical milling. During this process, manufacturers use maskants like: tape, paint, rubber elastomers or plastics. They cut the maskant pattern in the same shape the metal is to be cut. They then apply acid, called the “reagent,” to the exposed areas. When they’re ready, they remove both the masking and the reagent to reveal a finished part. Acid etching is used to create images, lines, grooves and holed surfaces.

Photochemical Machining

Photochemical machining is a little different from most variations of etching.

1. To start, manufacturers print the desired product shape on photographic film.

2. Then, they take a metal material, cut it down to size, coat it in photoresist, position it in between two sheets of film and vacuum seal the film and metal together.

3. Next, they expose metal to a UV light. This hardens the photoresist.

4. After that, manufacturers wash away any extra photoresist, so that all that is left areas they want to etch.

5. Once the extra photoresist is gone, they apply the etchant, which quickly eats away the exposed metal.

6. When the metal has been etched to satisfaction, manufacturers neutralize the etchant and wash it away.

Laser Etching

Laser etching, or laser engraving, uses a laser to remove material from metal pieces. It is favored for its ability to create very fine, clean lines on surfaces with little need for touch-ups. Laser etching is very popular in the jewelry industry.

Wet Etching

Wet etching is metal etching performed with a liquid etchant. This form of metal etching is comprised of four basic steps:

1. Manufacturers apply maskant.

2. Manufacturers apply the liquid etchant, which fuses onto the surface material to be removed.

3. The liquid etchant and the metal being etched react with one another, and the metal is etched away. This reaction is usually classified as reduction-oxidation, a process during which target material is oxidized then dissolved.

4. By-products diffuse.

Dry Etching

Dry etching replaces the typical liquid etchant solution with gas or plasma. During dry etching, manufacturers focus the kinetic energy of particle beams on the material. This energy, together with the created chemical reaction, etches the metal. Dry etching is subdivided into physical dry etching and chemical dry etching.

Physical Dry Etching

During physical dry etching, metal is etched without a chemical reaction. Instead, the kinetic energy produced by ions, electrons or photons does the job.

Chemical Dry Etching

Chemical dry etching, for vapor phase etching, relies on chemical reactions generated by chemicals like: chlorine gas, fluorine, sulfur hexafluoride, nitrogen trifluoride or tetrafluoromethane.

Electro Discharge Machining

Electro discharge machining (EDM) achieves exceptionally close tolerances by exposing the metal part to streams of corrosive electromagnetic discharge. Once complete, manufacturers remove any marks, burrs or other imperfections.

Benefits

Metal etching offers a wide variety of advantages, no matter which method you choose. For example, metal etching is universal; it can be used on countless metal materials and alloys. The process can even be applied to soft plastics and some glasses. Also, metal etching does not create internal stress, deformation or waste material. It is very rare that is causes imperfections. So, it requires little to no secondary tooling. Another benefit of metal etching is the fact that it requires no hard tooling. Also, manufacturers can perform it rapidly and accurately, and easily make design changes if needed. Finally, metal etching does not alter material properties.

Things to Consider

Before consulting with a metal etching manufacturer, we recommend you create a list of your specifications. Think about things like: your request volume, the level of design precision you seek, the depth of cuts you seek, your industry requirements, budget, your timeline and your delivery requirements. Knowing the details of what you seek will help you and a potential service provider figure out if you’re the right match for one another. Once you’ve got your list ready, check out the quality metal etching companies we have listed on this page. We’ve put this list together so that you don’t have to concern yourself with the information overload that is a Google results page. Though all of those we’ve listed are great companies, they’re not all going to be right for you. The right manufacturer for you will be the one that best fits your needs. To determine who that might be, take some time to browse their profiles. Pick out three or four to whom you’d like to speak directly, then reach out to discuss your specifications. Once you’ve talked to all of them, compare and contrast your conversations, and pick your manufacturer.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

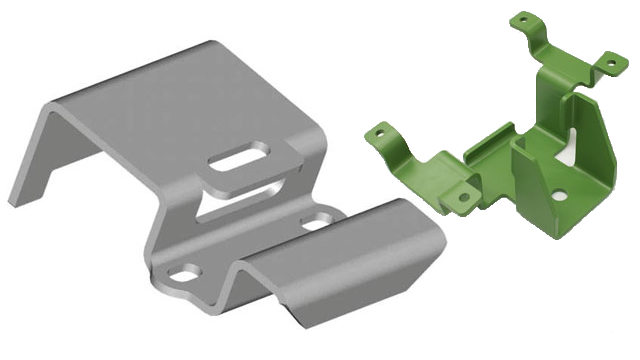

Metal Etching Metal Fabrication

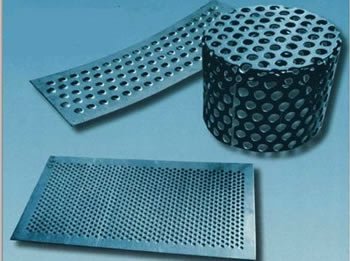

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services