Northwest Etch Technology

Northwest Etch TechnologyRequest A Quote

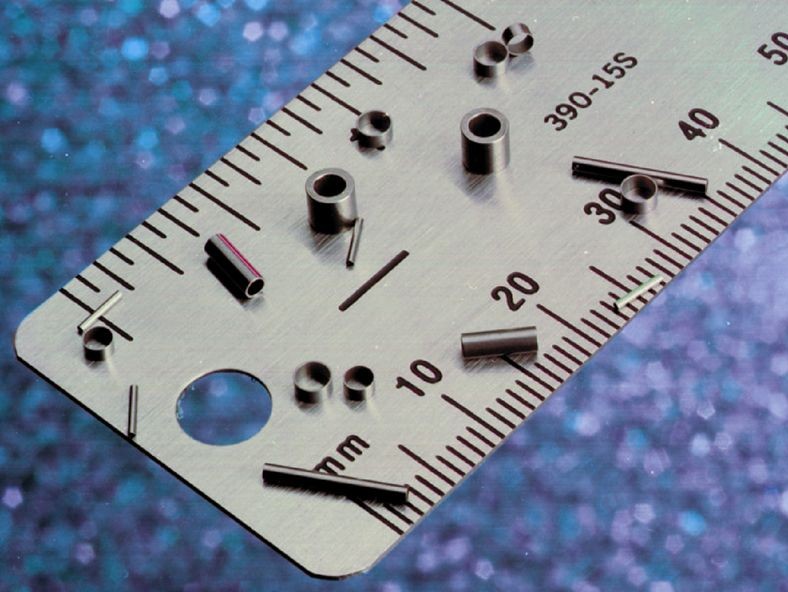

Tacoma, WA | 800-343-2401Northwest Etch Technology is a leading company specializing in the manufacture of metal etching products and providing a wide range of high-quality services to its customers. Founded in 1985 and located in the Pacific Northwest region of the United States, the company has gained a reputation for excellence in the precision metal etching industry. The primary focus of Northwest Etch Technology is the production of precision metal parts and components through the process of photochemical etching. This process, also known as chemical milling, is a highly precise and cost-effective method of producing complex metal parts with fine tolerances and intricate geometries. The process involves the use of a photoresist to selectively remove metal from a sheet or strip of metal, leaving behind the desired pattern or shape. Northwest Etch Technology serves a wide range of industries, including aerospace, medical, electronics, telecommunications, and automotive. The company's metal etching capabilities enable it to produce custom parts and components that meet the unique needs of each customer. With a team of skilled engineers and technicians, Northwest Etch Technology can work closely with its customers to design and manufacture high-quality metal parts that meet their specific requirements. In addition to metal etching, Northwest Etch Technology offers a range of value-added services, including plating, forming, welding, and assembly. The company's plating capabilities include gold, silver, nickel, and tin plating, among others. Northwest Etch Technology's forming capabilities enable it to produce complex shapes and contours, while its welding and assembly services allow it to produce complete assemblies and sub-assemblies. Northwest Etch Technology is committed to providing its customers with the highest quality products and services. The company has achieved ISO 9001:2015 certification, which demonstrates its commitment to quality management systems and continuous improvement. Northwest Etch Technology also maintains strict quality control processes throughout its manufacturing operations, ensuring that each product meets the highest standards of quality and precision. In conclusion, Northwest Etch Technology is a highly reputable and reliable company in the metal etching industry. Its precision metal etching capabilities, combined with its value-added services and commitment to quality, make it a preferred supplier for many companies in a wide range of industries. Whether it's a simple component or a complex assembly, Northwest Etch Technology has the expertise and experience to deliver high-quality metal parts that meet the exact needs of its customers.

Broaching

Broaching CNC Machining

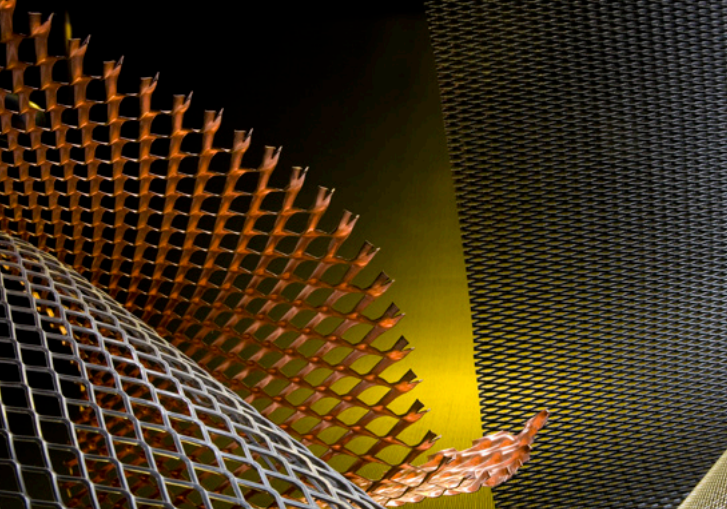

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

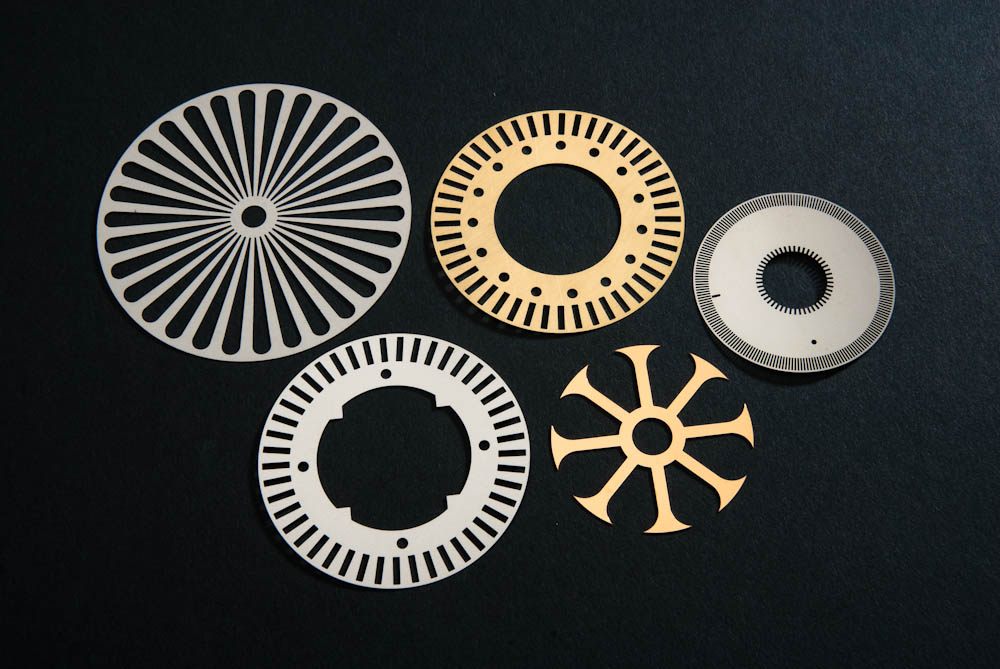

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

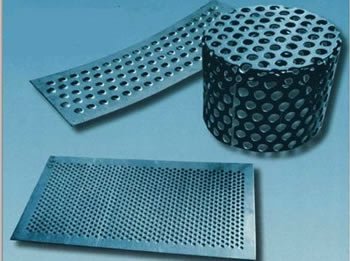

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

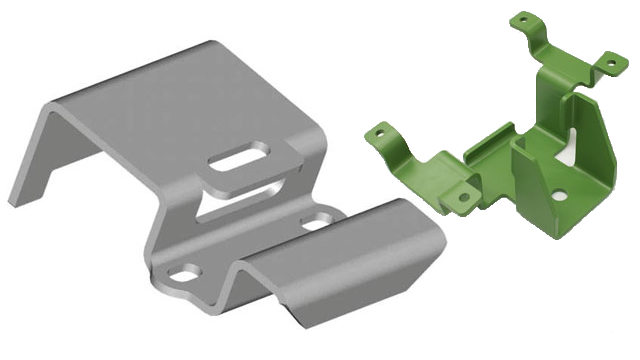

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services