Tech-Etch, Inc.

Tech-Etch, Inc.Request A Quote

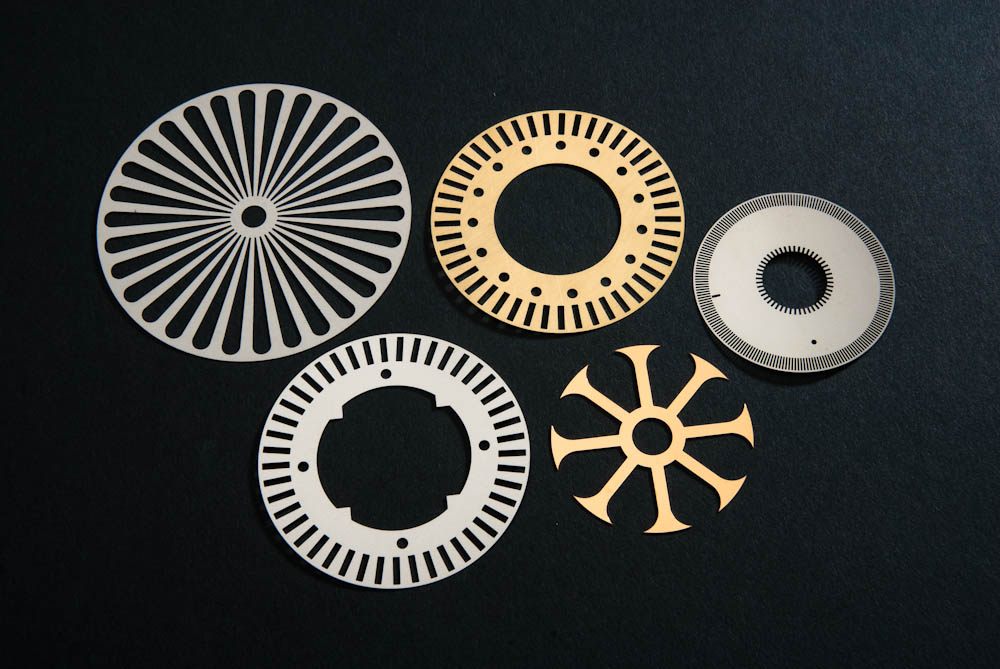

Plymouth, MATech-Etch, Inc. is a leading provider of precision metal parts and components using advanced metal etching techniques. Founded in 1966 and headquartered in Plymouth, Massachusetts, Tech-Etch has established itself as a premier supplier of precision metal components to a wide range of industries including medical, aerospace, defense, and electronics. Metal etching is a highly precise process that involves selectively removing material from a metal substrate using chemical or electrochemical reactions. Tech-Etch has perfected this process over the years, developing a range of innovative etching methods that allow for highly precise, repeatable results with tolerances as tight as ±0.0005 inches. The company offers a wide range of metal etching products and services, including custom metal components, EMI/RFI shielding solutions, flexible circuits, and precision-formed parts. Tech-Etch's etching capabilities include photochemical machining, laser cutting, and electroforming, allowing them to produce parts in a variety of materials such as copper, stainless steel, and titanium. One of Tech-Etch's key strengths is its ability to work closely with customers to develop custom metal components that meet their exact specifications. The company's team of experienced engineers and designers work closely with customers to understand their needs, offer design recommendations, and produce high-quality components that are delivered on time and on budget. Tech-Etch's commitment to quality is evident in its ISO 9001 and AS 9100 certifications, as well as its commitment to lean manufacturing and continuous improvement. The company also operates a state-of-the-art clean room facility for the production of medical components, ensuring the highest levels of cleanliness and quality. In addition to its metal etching capabilities, Tech-Etch also offers a range of value-added services including plating, welding, and assembly. This allows customers to receive fully finished components that are ready for use in their end products. Overall, Tech-Etch is a trusted partner for companies looking for high-quality metal etching services and precision metal components. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a leader in the industry and continues to push the boundaries of what is possible with metal etching technology.

Broaching

Broaching CNC Machining

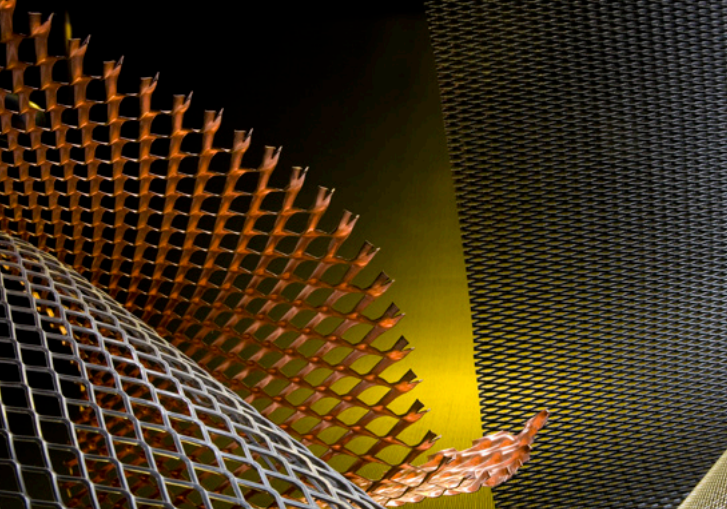

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

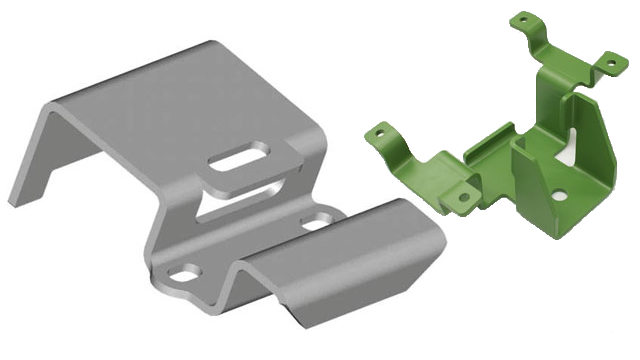

Metal Etching Metal Fabrication

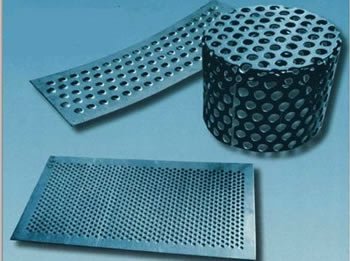

Metal Fabrication Perforated Metals

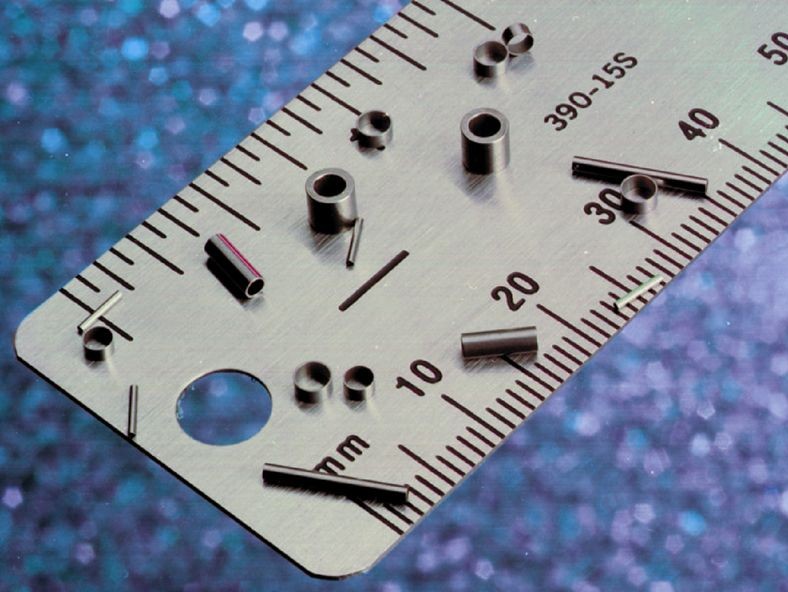

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

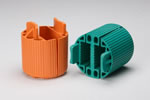

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services